What does “Non-Newtonian” really mean when it comes to bowling lane conditioners?

So, you know that non-Newtonian liquids are just like ketchup; you have to apply some force to make the liquid flow. But, what does “non-Newtonian” really mean?

You’ve likely heard of the English mathematician and physicist, Sir Isaac Newton. He is, after all, one of the most influential scientists of all time. He formulated the laws of motion and universal gravitation, laid the foundations of classical mechanics, and had a hand in developing calculus. He even did a lot of work in optics and built the first practical reflecting telescope!

Newton developed several scientific laws that described the relationship between forces, bodies, motion, and responses. You probably studied his three laws of motion in high school physics. You may have even studied Newton’s law of viscosity in school; though you may not have realized it!

Newton’s law of viscosity isn’t a fundamental law of nature (like the laws of motion or gravity). Rather, it is a relationship between two physical quantities; in this case, viscosity and force (called shear). When viscosity doesn’t change no matter how much force is applied; i.e. when viscosity is independent of shear; you have a Newtonian fluid. Most fluids are Newtonian and the most common one is water. Under normal conditions, the viscosity of water doesn’t change no matter how much force; or shear; is applied.

There are different kinds of non-Newtonian fluids; shear-thinning and shear-thickening are two of the more common kinds. The viscosity of these fluids will change depending on the amount of force that is applied. A shear-thinning fluid will experience a decrease in viscosity with more applied force while a shear-thickening fluid will experience an increase in viscosity with more applied force.

Ketchup is the perfect example of a non-Newtonian, shear-thinning fluid. You can turn the bottle upside down and wait for the ketchup to flow and it just never seems to happen. Give the bottle a couple of solid taps on the palm of your hand though, and the ketchup starts to ooze out of the bottle. The force applied to the bottle caused the viscosity of the ketchup to decrease (the ketchup became thinner) enough so that the ketchup would flow from the bottle. Once a force is no longer being applied; i.e. the ketchup is on the plate; the ketchup returns to its original viscosity and sits in a blob on the plate.

All that is cool, but how does this relate to lane conditioners?

Well, with a non-Newtonian conditioner, each bowler will see slight variations in ball motion. For example, a high-rev, high-speed player; here’s looking at you, cranker; will apply a lot of force to the conditioner. As such, the shear applied to the conditioner will cause the viscosity of the conditioner to decrease. This will allow the player to see a little more push; the ball will skid where it needs to skid. A low-rev, low-speed player; that’s all you strokers out there; will apply a lot less force to the conditioner. The shear applied to the conditioner won’t cause as much of a decrease in viscosity as the cranker saw. As such, the stroker will see a little more friction so the ball will read and pick-up where it needs to pick-up. In simpler terms, the stroker will see “good friction” while the cranker will see a little more slickness.

Of course, this is all on a very small scale. A 200 rev rate bowler might “see” the viscosity as 70 cps while a 500 rev rate bowler might “see” the viscosity as 65 cps. In the scheme of viscosity, 5 cps is very small. So, what the ball; and the bowler; see is very subtle. But, it’s just enough to help all bowlers find good ball reaction.

Learn more about Kegel’s non-Newtonian Lane Conditioner, Terrain.

New Product Lifecycle

Have you ever wondered about the process of creating a new conditioner? How do we test? What do we look for when we’re testing? How do we choose test centers? How does field testing work? If you’ve ever wondered about the research and development process, or if you’ve ever thought you might like to be a test center for a new product, keep reading.

Creating a new conditioner is a lot like baking a cake without a recipe; you know how you want the cake to look and taste and you know you’ll need some flour and sugar. But, you don’t have an actual recipe so you have to figure out the rest of the necessary ingredients in order to get to the desired result.

Creating a lane conditioner can follow that same concept. In general, mineral oil is the “base” so we’ll likely use some combination of mineral oils to start. After that, we experiment with different combinations of chemicals to try to achieve the results we want to see. Since we’ve been in the lane conditioner business for quite some time, we have a solid foundation of knowledge of many raw materials. We know that some materials will give us more “slickness” while other materials may help the conditioner be “hookier”. We constantly search for new technologies to help us create the best lane conditioner we can.

Once we have a formula, we start testing. For lane testing, we generally use a house pattern and we’ll use the same house pattern throughout testing so that we have an equal comparison when we make formula adjustments. We are fortunate to not only have our Batch Test bowlers, but some extremely talented bowlers throughout our building. So, we take full advantage and use them when we’re testing a new product. We try to use a variety of bowlers so that we can see how the conditioner performs for bowlers of different styles. And, as much as possible, we try to use the same set of bowlers throughout a product test. While they’re bowling, we’ll track scoring, bowler moves, and we’ll make notes on things like ball reaction, residue on the bowling balls, and carry down.

In the lab, we’ll test physical properties like viscosity, density, and surface tension. These properties give us some general characteristics about the conditioner like how it might flow on a lane. We also do temperature stability testing. We’ll put samples through freeze/thaw cycles to see if the conditioner is impacted by cold and we’ll do heat ramp studies to see if the heat negatively impacts the conditioner. We even do chemical compatibility studies. Belts and other materials from pinsetters, tubing and other parts from lane machines, and other materials that could contact the conditioner are cut into pieces and soaked in the conditioner as well as in some of the raw materials. We measure the parts before we soak them and then measure them again after one month. This helps us determine if the chemicals will create any issues with the parts.

The next phase of testing for a conditioner is field testing. Initially, we’ll test in one or two centers to make sure the product will perform well. We work with the centers to understand what they see from the conditioner using their normal pattern and maintenance routines. They provide feedback and we work together with them to make pattern adjustments, machine adjustments, and such to try to improve the performance. We track all of these changes and use the information to determine if we need to make adjustments to the product. If we make adjustments, we continue testing until we get to the point where we feel confident that we’ve created a viable product.

Next, we continue adding centers to our field test. Ultimately, we like to have at least 15 centers test a product for several months. We try to cover as many different variables as possible by using centers all over the country. By testing on different lane surfaces, pinsetters, ball returns, and so forth, we can determine if the conditioner will be a good fit for different combinations and in different environments.

While the product is in field testing, we continue collecting data in lab testing. We send samples to partner labs for analytical testing like flash point and fire point testing. These tests allow us to determine proper packaging and shipping requirements. We also submit a sample to USBC for approval. In order to gain USBC approval, a lane conditioner must meet the required specifications for viscosity and UV content.

As we continue with field testing, we keep notes on pattern adjustments made by each center. This helps us learn what works; and, more importantly, what doesn’t; with patterns on different surfaces. We use this information once a product is released to the market so that we can give our customers educated adjustments for their patterns when they switch. What that means is you can switch with a little less trial and error and a few less irate bowlers.

Just before we release a product to market, we build all of our marketing and sales materials. We use information we gathered from our field testers and data we collected during our various phases of testing. We conduct in-house training for our Techs, Customer Service, and Sales staff. And, we start making batches in preparation for sample kits. Our goal is to release the conditioner to the market in the summer so that your center has time to try it and fine tune your pattern before your fall leagues start again.

Now, all this may sound glamorous, but many of our test centers would likely tell you that testing isn’t always rainbows and butterflies. It can get ugly and you certainly have to be willing to make your bowlers angry. When we send a center a new product, we request that the center try the product without making any changes to their normal procedures and pattern. So, if a center had been using a conditioner that was characteristically hookier, and we asked them to use a conditioner that is slicker, the bowlers would see something different than what they’re used to seeing. And, if scores go down, it could make for some pretty angry customers. Test centers can’t be reactive to that though. We need centers who can give us quality feedback and that are willing to make the adjustments we suggest based on their feedback. We need centers that will work with us as we work through issues and try to improve the situation. It can take some time to fine tune the adjustments and we need centers that are not going to throw in the towel while we work through the chaos. The rainbows and butterflies come when we get the right adjustments and scores go up and bowlers comment about not moving as much during a league session. Being a test center can be as frustrating as it can be rewarding.

We do our best to create products that solve a problem or fill a need in the industry. The process takes a lot of time and it involves a lot of people. If we didn’t have customers to give us valuable feedback and we didn’t have test centers we could trust to help us during the development process, we wouldn’t be able to create solid products. We count on our customers to tell us what they think and even what they need as we continue to create products to improve the bowling experience.

If you’ve made it this far and still think being a Kegel test center sounds pretty darn awesome, you can reach out to our Kegel team to see if you qualify. You can also fill out our Test Center Information Form so we can gather all of your center specifics.

5 Must Know Things about Oil Pattern Taper

Oil pattern taper, the amount of lane conditioner in the front part of an oil pattern versus how much is at the end of the oil pattern, has had to change significantly as bowling ball technology has changed. Lane conditioner (lane oil) has two main functions; to protect the lane surface, and to provide smooth predictable ball motion for as many styles as possible.

1 - History

When bowling balls were balanced, the rotation of the bowling ball was very stable and there was essentially one oil ring on the surface of the ball. Front-to-back oil taper with balanced balls is very different than what is needed with modern high flaring balls, which have multiple oil rings on them.

Remember, with high flaring balls, the oil pattern breaks down from back to front and with low flaring balls it’s the opposite, oil patterns break down from front to back. As a refresher, here is an article on that explains how oil patterns breakdown differently between the two types of bowling balls: Breakdown and Carrydown – Then and Now.

At the same time that bowling balls were going through changes, lane surfaces were also changing – “it’s very hard to hit a moving target” was something John Davis used to say often when referring to the art of lane conditioning.

As we have shown often in seminars and online articles, regularly maintained wood bowling lanes are the most consistent type of lane surfaces from lane-to-lane, and bowling center to bowling center. There may be some lengthwise level differences from center to center, but the overwhelming majority of wood lanes were cut with a slight depression, which allowed statements like “the oil pattern taper should be 3:1” to be more valid.

With synthetic lanes however, lane shapes are all over the map, and blanket statements about front-to-back taper, or any oil pattern statement for that matter, can often do more harm than good for people trying to find the best solution for their bowling center.

In measuring hundreds of bowling centers around the world with the Kegel LaneMapper we have found the lanes in any one center follow the same trend as it relates to lengthwise levelness. The only exception to that rule is when bowling centers have added sections of lanes over time.

So if we simply talk about oil pattern taper as it relates to the lengthwise level of a bowling lane, if a lane went downhill we could easily increase the front-to-back taper ratio to help the ball slow down to achieve “good ball motion”. Conversely, if the lanes in a bowling center predominantly go uphill, we might decrease the taper of the oil pattern so the ball would slow down less in order to provide good ball motion for the majority of bowlers.

When lanes were made of wood and resurfaced often, and bowling balls were essentially balanced, it was that simple – but not today.

Today’s synthetic lanes can be crowned, they can be depressed, they can be depressed up front and crowned down lane or the opposite, they can be high right, high left, and anything in between. We very often have seen synthetic lanes that are shaped like a seagull wing; crowned outside and depressed in the middle.

Add the fact that your customers have bowling balls that are still balanced (low flaring) to the very unbalanced kind (high flaring), providing that perfect front-to-back taper can be a challenge.

Of course your daily house pattern is most important for your center, and getting that one pattern “right” can be accomplished, but applying a tournament pattern, or one of the many named patterns out there, and having players expecting it to play similar from center to center is like expecting to win the lottery.

2 - House Shot Patterns (Recreational Type)

Most daily patterns used in bowling centers around the world are of the easy variety – a lot of conditioner in the middle and not much outside. For these type oil patterns, it is most important to control the amount in the mid lane and at the very end of the pattern to 1, minimize carrydown and 2, to open up the outside portion of the lane.

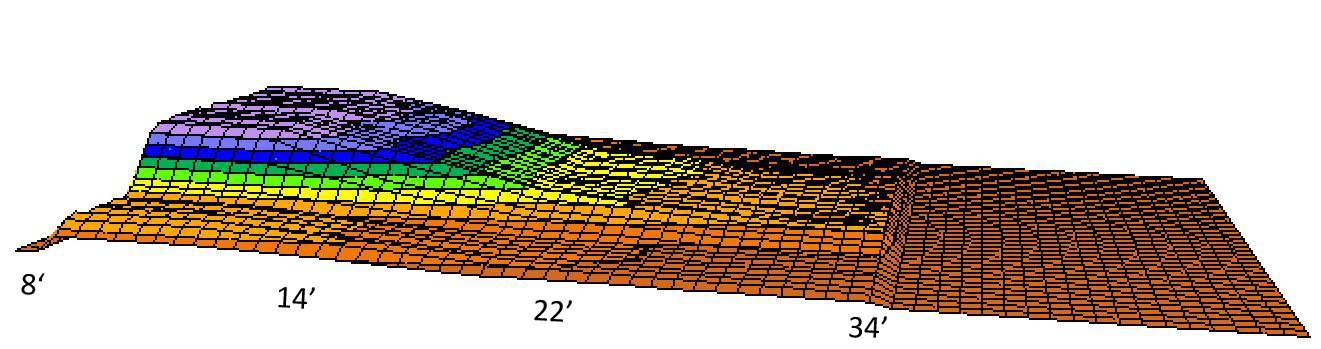

The graphic below is of a typical oil pattern taper when only non-flaring balls were in use. The goal then was to protect and apply conditioner only in the head area and let the conditioner “bleed off” the oil transfer system the rest of the way down the lane to the end of the oil pattern. From 8’ to the end of the pattern was typically a front-to-back taper ratio of 3-4 to 1 and that was with a maximum of 20 units in the head area!

Today’s oil patterns with today’s high flaring balls require a different type of taper, and much more volume. If we start with 80 plus units in the heads, there might still be 50 plus units in the middle to the 30 foot range. We do this in order to provide the bowler with a lot of hold area and decent ball motion, along with providing durability to protect the lane as long as possible.

To get that amount of oil throughout the pattern, the buffer brush must be loaded much more throughout the oil pattern with possibly a much more drastic drop off of conditioner towards the end part of the pattern. The amount towards the end of the pattern should decrease at a rate according to the type of lane conditioner in use and/or lane topography.

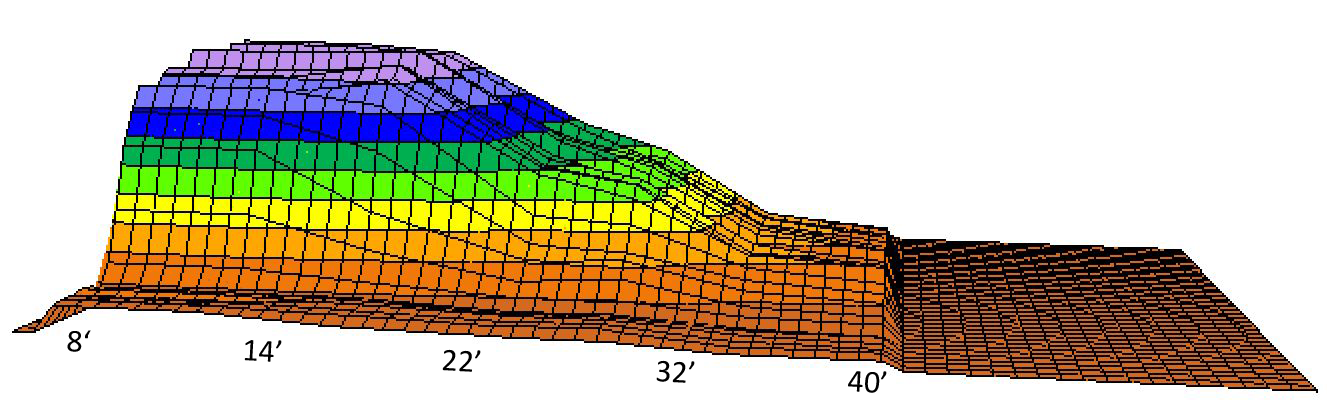

Below is an example of a typical daily oil pattern taper using high flaring bowling balls. As you can see, much more conditioner is used throughout the entire pattern.

The outside portion of the pattern has very little conditioner because most centers want to provide the bowler with a lot of mistake area outside of target. So even though we may want some taper there to allow the straighter player to start more to the right, most are concerned about not having too much conditioner towards the outside area in order to provide the largest margin for error possible.

3 - Challenge and Sport Oil Patterns (Competitive)

When designing competitive oil patterns, the goals of a specific oil pattern can vary greatly. If the pattern must play good on the fresh, because of a match-play format for example, finding that perfect taper for game one might be in order. That type pattern will usually be a higher front-to-back taper ratio in order to get the ball to read the lane sooner within the oil pattern.

If the goal is for the pattern to keep players in a specific zone for a longer time, front-to-back taper might not be as important as making sure the end of the pattern holds up for more games. That type of pattern would most likely have much less taper and play more difficult on the fresh, and then become easier as depletion towards the mid and end part of the oil pattern occurs.

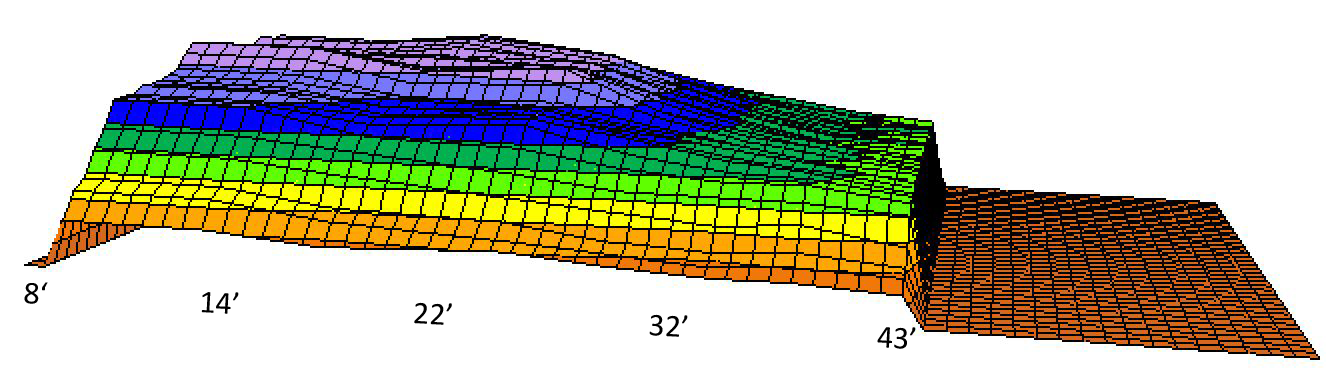

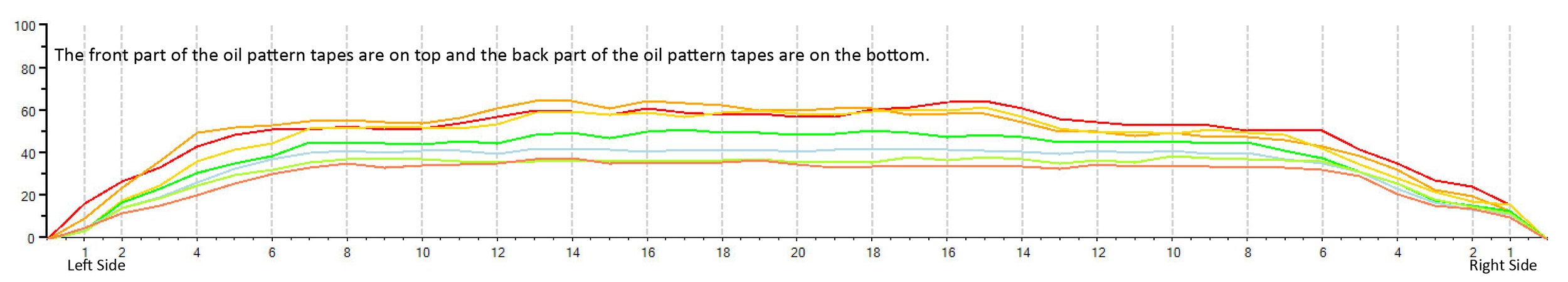

A perfect example of an oil pattern with very little front-to-back taper is the 2015 US Open pattern that was used in Garland Texas. The amount of oil in the middle at 8’ on this pattern proved to be in the high 50 unit range, at 22' in the mid 60 unit range, and at 2’ before the end of the oil pattern (41') was in the mid 30 unit range. The front-to-back taper in the middle of that oil pattern was about 1.75 to 1 from 8' to 41', and 2 to 1 from 22' to 41'.

Below are two graphics of the 2015 US Open oil pattern – the 3D and 2D graphs. Lane tapes were taken at 8, 14’, 22’, 27’, 32’, 36’, and 41’.

The pattern goal of that event was to try and keep the players from lofting the gutter, which was accomplished, but we cannot discount what was done with topography at that venue as well. Our studies show topography is always a factor in how oil pattern plays, develops, and breaks down. In this case, the USBC made topography public so we know lane topography definitely was an additional reason the pattern held up so well. (The why will be a future article!)

4 - Lane Conditioners

The lane conditioner you choose also must be factored into your oil pattern’s design. Lane conditioners are developed with specific characteristics and your oil pattern should complement those characteristics in order to benefit from them.

For instance; FIRE and ICE were created for increased durability and both require less conditioner at the very end of the pattern than many of our previous conditioners. If there is too much conditioner at the end of the oil pattern the ball will read the carrydown much more than if, for example, the same amount of Prodigy was at the end of the pattern.

If using our newest lane conditioner, Curve, more conditioner can be applied at the end of the oil pattern simply because it’s a higher friction conditioner, and that will help the ball slow down. Also, the ball won’t “see” what is carried down beyond the oil pattern as much as it would with FIRE or ICE. The trade-off however is durability.

5 - Topography

Now that we have those other factors covered, we can touch base on topography some more and how lane shape affects oil patterns. As we touched base earlier, wood lanes have very similar topography; all are slightly depressed (lower in the middle than the outsides) with the main differences from center to center in lengthwise levelness.

Yes we have more wear issues with wood lanes, which can be corrected with a resurfacing or re-coating, but with synthetic lanes we have more diverse shapes on the lane than ever before in the modern history of the game. Those shapes can vary from lane to lane, and even within the same lane. This makes finding that perfect oil pattern on synthetic lanes across any one bowling center more challenging than ever.

For lanes that are predominantly crowned, lowering the amount of conditioner in the mid lane and at the end of the pattern will help the ball lose energy at the proper rate, which will help provide truer ball motion. Crown lanes tend to act like lanes that go downhill, so anything you can do to help the ball slow down will help your bowlers with good ball motion.

For lanes that are severely depressed, and if you wish your bowlers to play right of center, additional conditioner in the mid lane and at the end of the oil pattern helps reduce friction slightly, and therefore helps the ball not lose energy as quick. Think of depressed lane like a banked curve on a race track – the inside part of the lane is lower than the outside part of the lane so the ball is rotating up the hill causing it to use energy quicker, along with normal force helping the ball move more to center.

For seagull wing shaped lanes, and believe us when we say there are many overlays like this, shorter patterns will need increased front-to-back taper in order to get the ball to read the lane earlier. Yet longer patterns on this lane shape will need less taper simply because from 10-10 the lane is depressed - once the ball gets towards the middle and end part of the pattern it sees the lane more, and sooner, as the oil depletes.

Conclusion

In the article titled Breakdown and Carrydown - By The Numbers, we showed how today the front part of the lane never really depletes to the point of excessive friction unless there is a major wear issue – it’s the mid lane and backend that deplete to the point of the ball seeing a great amount of friction.

Sure the front part of the pattern depletes, but if we start with 70-100 units up front, or less like in the US Open example, at the end of play there is still 30 to 40 plus units of conditioner in the front part of the lane, which is plenty to provide a low amount of friction.

In addition, that part of the lane the bowling ball has the least amount revolutions and the most amount of speed - both of those attributes make the ball “see the lane less” than it does at it slows down and revolutions increase.

The point is, front-to-back taper ratios with today’s patterns is not as important as controlling the amount of conditioner in the mid lane and at very end of the pattern.

If you get that correct in your center, the majority of bowlers in your center will have predictable and controllable ball motion, and back end change (carry down) will be minimal. And for the most part, hopefully, you will have happy bowlers.

Balance Approach All-In-One: What, Why, and How

Giving your bowlers consistent approach conditions from day-to-day may often seem like rocket science. There are a plethora of approach cleaners and approach conditioners on the market. And, there are an abundance of tools to help you in your quest for consistent approaches. Which ones to use; that’s the real question.

Approach cleaners help remove dirt, spills, sticky materials, and other foreign residues from the approach while approach conditioners leave an invisible film that helps reduce the coefficient of friction giving more slide-ability to the approach. These products are often great; initially. But, after a game or two, the film in the slide area gets worn and causes inconsistency between the slide-area and the corners. When this happens, the slide-area is tackier and the sides are slicker (or vice versa) leaving the bowlers with, yet again, inconsistent approach conditions.

We developed Balance with this in mind. We wanted to create a product that was simple to use and that would create a consistent slide environment for bowlers. We also wanted to create a product that would clean and condition the approach in one step.

With Balance, you no longer need a separate approach cleaner and approach conditioner; it’s an all-in-one product that can solve many of your approach problems.

Balance is gel formula that must be applied with a rotary buffer and a buffing pad. A thin bead of Balance is applied parallel to the foul line and about six or so inches in front of the foul line. Using a rotary buffer and the white or green-striped buffing pad, Balance is buffed into the approach beginning at the foul line, working backwards towards the ball return and then back to the foul line. While buffing, there is a visible film that appears. Once the film is no longer visible, the approach is complete.

The buffing pad can be used for multiple lanes. However, once the pad gets saturated, you will need to either flip the pad or use a new one. You can easily tell when the pad is saturated as it will take a long time for the film to disappear, if at all.

Balance won’t leave your approaches slick or tacky. Rather, it evens the sliding environment to make the approach consistent from gutter to gutter. It is recommended to be used weekly or as needed. Because it cleans the approaches and conditions them simultaneously, Balance eliminates the need for multiple products and saves you time by eliminating multiple steps in the approach maintenance process.

Approach maintenance no longer needs to be a difficult task that leads to consistently inconsistent approaches. With Balance, one product cleans and conditions your approaches helping you achieve even sliding approaches across your house while simplifying approach maintenance.

Synthetic Approach Maintenance

Let’s face it; approach maintenance can be a sticky, or slippery, business. There is a fine line to walk when trying to keep the approaches as consistent as possible. Some products offer too much slide causing bowlers to slip while other products can leave behind films and tacky residues that could cause bowlers to stick. Both scenarios are a recipe for disaster that could lead a bowler to an unplanned “Machuga Flop”. And while a flop can be funny, we all know it can hurt and it’s uber embarrassing. But, what is a bowling center to do? How can you maintain the delicate balance of not too slick and not too sticky? We’ve got the answers to your approach maintenance questions.

Some history

Before there were synthetic approaches, all approaches were made of wood and coated with a finish that allowed for proper slide. The only real maintenance to be done to these approaches was the occasional spot cleaning for spills and sticky marks and daily dusting. Then, once every year or so, the approach needed to be sanded and recoated to “refresh” the finish. Wooden approaches have a fairly even slide as long as the finish isn’t worn down. Once the finish started to wear, the approach could be spotty. Generally though, this was just an indication that it was time to refinish the approaches.

Synthetic approaches were introduced when synthetic lanes were introduced. Synthetic approaches were virtually maintenance-free since they eliminated the need for refinishing - or so it was thought. Synthetic approaches came with their own set of problems.

Think of synthetic approaches like your kitchen countertops; not the granite, marble, Corian, and fancy varietals, but the Formica and laminate variety. Layers of materials are pressed or bonded together and an outer layer with the approach image is pressed or bonded to the top. The top layer on which a bowler will slide is often textured and porous. This means dirt and residues can get into those tiny pores and cause build-up. It also means that repeated sliding in the middle of the approach can wear down the texture and cause inconsistencies in the slide-ability of the approach from the middle to the sides.

Because of these issues, a variety of different products and procedures have been developed to help bowling centers maintain their approaches. And what was once billed as an approach that was basically maintenance-free has now become even higher maintenance.

So what’s the right way to maintain synthetic approaches?

If I were to ask 50 different people the proper way to maintain the approach, I’d likely get many different answers. There would be variations of cleaning techniques that used various cleaners and solutions and even just hot water. There would be dust mops, wet mops, buffers, and spot cleaners. The only consistent thing would be that bowlers still complain and the approaches are inconsistent. It’s a vicious and never-ending cycle.

Synthetic approaches require temperature and humidity control. I did some digging, well, Googling, and I found that humidity over 50% can cause approaches to be tacky. We all know tacky isn’t good when trying to slide. To combat this, having some temperature control in the bowling center is absolutely necessary. Additionally, having circulation that pulls or pushes moist air away from the lanes/approaches can help keep moisture from the air from settling onto the approach. The optimal humidity is around 40%.

Dusting the approaches is a necessary task. Dust can settle on the approach and get embedded in the pores. Aside from just causing the approach to look dirty, dust can cause inconsistent slide-ability as well. Dust can cause approaches to be slick and, well, too slick is just as bad as too tacky.

Spills happen

It’s important to clean the spills and wipe away residues. Lane conditioner, soda, beer, and an infinite number of other materials can be spilled on the approaches and every one of them can cause sliding issues. When something is spilled on the approach, wipe it up as soon as possible with a clean, dry cloth. Use a weak dilution of cleaner to remove any sticky liquids. Go back over the area with another clean towel and some IPA (isopropyl alcohol). IPA is very good for removing sticky residues and leaves no residue behind of its own. It isn’t a “cleaner” but it will help remove sticky residues.

Clean those carpets and floors!

The carpets and flooring areas around the bowler’s circles must be kept clean as well. Wax from tiles and residues from carpets and carpet treatments can stick to shoes and can easily be tracked onto the approach. It’s just as important to keep the non-bowling areas clean as it is to keep the bowling areas clean. And, be careful what products you choose for cleaning. Many cleaning products leave behind residues and, as I said before, the residues can easily be tracked onto the approach.

The quest for consistency...

When all of this is done, sometimes you still need some help getting consistent slide on your approaches. There are many products on the market designed to help you with this. Unfortunately, so many of the products available have their own sets of issues. When sprayed, they can get on the lane surface and cause issues with the lane conditioner and pattern.

Dust type products can leave dust residue on the lane and the residue can settle in nearby areas. Some products have to be used very sparingly or the approach can end up being too slick. Some products work great when you first use them, but then after a couple of games, the approach is inconsistent again because the product has “worn off” in the slide area leaving the outsides slick and the slide area tacky.

All of this can be a big frustration. And, it’s one of the common complaints that we hear when dealing with approach questions. People just want a process that is simple and they just want the approaches to be consistent. In fact, I’ve heard from many bowlers that they wouldn’t mind the approaches being a little on the slick side or even a little on the tacky side as long as the approaches could be consistent from the ten pin side to the seven pin side. Bowlers can adjust for a little more slide or a little more stick. But, it’s nearly impossible to adjust when there isn’t any consistency across the approach.

To sum it up, synthetic approach maintenance can be tricky. It can be time consuming and tedious. And, with all of the approach maintenance products available, it can be downright overwhelming. But, the good news is, it doesn’t have to be. Giving your bowlers consistent approaches doesn’t have to be such a mind-boggling task. You can give your bowlers the left-to-right consistency they want on a day-to-day basis with Balance, Kegel’s new synthetic approach maintenance product. To learn more about Balance, click here.

Does lane oil evaporate and how long should the oil pattern sit?

When it comes to lane conditions, every person has their own ideas as to what they think works best. Mechanics, proprietors, and bowlers all have a difference of opinion when it comes to dressing the lanes. Ask 100 different people and you’re likely to get 100 different answers. In bowling, it’s one of those topics that just seems to create a lot of controversy and a lot of differences in opinions.

Because of all these different opinions, we get many questions regarding what the best methods are for ensuring lanes are the same from day to day. Some of these questions stem from curiosity while others, like the one I got last month, stem from bowler controversy.

I was forwarded a message that came in from our website. The proprietor was quite frustrated at his bowlers because his bowlers felt like the lanes were getting conditioned too early and the conditioner was “drying up” before they ever started bowling. The proprietor tried to show the bowlers statisitical data in their score trends that suggested otherwise. But, the bowlers just didn’t agree. So, he asked “the experts”; how long can an oil pattern sit on a lane before it starts to deteriorate?

Modern lane conditioners; every lane conditioner available in today’s market; are all mineral oil based. Kegel uses pharmaceutical grade mineral oil in our lane conditioners so it is of the highest purity available. Mineral oil itself doesn’t evaporate. You could fill a cup with mineral oil and leave it sitting and it wouldn’t evaporate. Here is a link to a safety data sheet (SDS) for white mineral oil. If you look in section 9 (page 4 of the document), it shows the evaporation rate as ‘NA’. This means there is negligible or no evaporation of the material.

There are some chemicals in lane conditioners that will evaporate but these ingredients are minor compared to the percentage of mineral oil. For example, solvents such as isopropyl alcohol (IPA) are often used as an inexpensive way to lower the surface tension. Lowering the surface tension will allow the lane conditioner to wet across the lane surface more quickly. Once the lane conditioner is applied, the IPA would evaporate over time. Since lane conditioners are applied in such a thin film with a low volume over a larger area, we would estimate this to be in the 30 minute range at most. It does not take a lot of IPA to lower the surface tension so it is used in amounts of 1% or less. This evaporation does not affect the lane play characteristics that come from the mineral oil and the other ingredients that are used to give the conditioner its characteristics.

While we’ve never tested the theory of how long a lane conditioner could sit before deterioration begins, a lane pattern could sit, well, forever without deteriorating. That is, of course, in theory since we don’t have a time machine! There are other things; environmental and atmospheric conditions; that will affect lane conditions. But, the conditioner itself could sit for days on the lane and it would still be there; it isn’t going to evaporate away.

While we haven’t tested the ‘forever’ theory, we have allowed a freshly conditioned lane to sit for 24 hours. We took tapes from the freshly applied pattern and took tapes on the same pattern 24 hours later. The results: the tapes were exactly the same for both sit times. The conditioner sitting on the lane didn’t change as a result of evaporation.

Other things can affect the conditioners performance though. Dust from the air or from AC vents can be deposited on the lane. These particles can greatly affect the playing characteristics of the pattern. This is one reason that a good cleaning routine is so important. Applying lane conditioner to a dirty lane will also affect the playing characteristics of the pattern.

Atmospheric conditions like temperature and humidity will also greatly affect lane play and these are more likely the cause of changing lane conditions. Bowling centers see this a lot as the weather changes, especially when there are sharp changes from cold to hot or hot to cold. Bowlers will complain that the lanes are tighter or drier or something else but they don’t always consider the weather changes and that can affect lane conditions significantly.

Here are two previous Inside Line articles that address changing weather and lane conditions: The Weather’s Changing… Are Your Lane Conditions? and Lane Conditions and Cold Snaps.

How long a conditioner should be allowed to sit on a lane prior to bowling is a very common question. And, it’s one that we’ve gotten many times. While consistency is key, we like to support our arguments with science. So, here’s a little science behind conditioner application.

When lane conditioner is immediately applied to a bowling lane, several things must happen before the lane conditioner stabilizes enough to provide consistent playing characteristics. One is allowing the lane conditioner to adhere to the lane surface. This takes about 15-30 minutes depending on the amount of conditioner applied, the type of conditioner, the type of cleaner being used, and the surface energy of a particular lane surface.

The surface tension of the conditioner is also important since the surface tension directly affects how the conditioner “wets” across the lane. The conditioner needs to “like” the lane in order for it to wet across. If the surface energies between the two don’t agree, the conditioner will “sit up” on the lane surface (think of this effect as little beads of water sitting on the surface of your car versus the water sheeting off the surface of the car).

Another bonding takes place within the lane conditioner molecules themselves. These bonding forces, known as van der Waals forces, are basically weak attractions between atoms, molecules, and surfaces. The time for this to take place after conditioning a bowling lane is also anywhere from 15-30 minutes. The below video shows these weak bon

With the amount of lane conditioner being used in today's lane patterns, it takes about 15-30 minutes for the lane conditioner to "settle down" and stabilize on the lane. If time is not allowed for this process to take place, things like excessive carrydown can occur. The lanes may also play "tighter" simply because the oil is sitting up on top of the lane more and there is less resistance to the bowling ball as it rolls through the oil pattern. This is one reason; during tournaments where we provide lane maintenance; we always try to get the tournament organizers to allow a minimum of 15 minutes of lane conditioner "sit time" before the first ball is thrown down the lane.

The biggest key is consistency. It’s one of the things that we preach. Create a routine and stick with that routine every day. If you do the lanes an hour before league, do them an hour before league every time and you’ll eliminate that variable (and that complaint from your bowlers).

We hope this information helps you. If you have additional questions, please feel free to contact us. We will be happy to assist in any way we can. Until next time, happy bowling!

Switching Lane Conditioners: Out with the old, in with the new!

Bowl Expo has come and gone once again. That means that summer is in full swing and league season will be upon us before you know it. As such, you may be thinking about trying a new lane conditioner, like Fire or Ice, before league season starts. These conditioners were released last year and they have been gaining attention because of their performance in tournaments and championships worldwide. Now is the perfect time to try one and get your pattern adjusted to be ready for fall.

Changing lane conditioners can be an overwhelming process. In fact, just the thought of it may send shivers down your spine. After all, if your bowlers have been happy, why change it and risk upsetting the balance? Well, technology has come a long way. We’ve worked hard developing conditioners that will help you protect your lane surface while providing a durable lane condition for your bowlers. And, we’ve improved the durability while allowing you to use less conditioner which saves you money.

Once you’ve decided to make the leap (and decided which conditioner to use – we’ll have more on that later), you’ll need to spend some time cleaning your lane machine. While it may seem easy to just empty the conditioner tank and pour in the new conditioner, you won’t be doing yourself any favors by doing this. Cross contamination from one conditioner to another in the same tank can wreak havoc on your lane pattern and make your lanes inconsistent. And that just leads to unhappy bowlers. No one wants that!

Additionally, some lane conditioners just don’t mix well with others.* This can cause things like clogged tubing, pencil tips, or even oil control valves. You can avoid a lot of headaches by taking some extra steps early on.

*The FLEX Lane Machine boasts the ability for centers to use two compatible conditioners simultaneously. Currently, Fire and Ice are the only compatible conditioners that can be used in this manner. Mixing other conditioners, such as Prodigy or Infinity, with Fire or Ice is not recommended.

Changing conditioners in the machine is a tedious process, but it is a process that is well worth it. Here is a brief overview of the process for Sanction Technology™ lane machines:

Remove the conditioner tank from the lane machine. Empty the contents of the tank into a waste container.

Use some lane cleaner to clean the conditioner tank. Add some of your lane cleaner solution directly to the tank. Swirl or shake the cleaner to get it all over the inside of the tank.

Rinse the tank with water. You’ll want to shake and swirl to be sure the tank gets completely clean. Continue rinsing until the water is clear (it will probably look milky at first) and there is no foam.

Rinse the tank with some acetone (if available) and let the tank dry. It is best to let the tank dry overnight, but give it as much time as possible. The tank needs to be completely dry before you add new conditioner.

Use this time to wipe down and perform any maintenance to the transfer system. This is also a good time to perform some cleaning and/or maintenance to the buffer brush.

Place the conditioner tank back in the machine.

Now you’re ready to fill the conditioner tank and flush the machine. We’ve detailed the entire process here: Changing Out Conditioners - Sanction Technology

So, I’m ready to fill my machine and flush the lines, but I don’t know which conditioner to use. Don’t worry; we’re here to help!

Fire and Ice have similar properties chemically but they yield different results on the lane. Both conditioners are pinsetter and house ball friendly meaning that you’ll have fewer issues in the backend. Both conditioners also have improved durability even with reduced volume.

There are a few factors that can help you decide which would be best for you. What conditioner do you use now? What is your lane surface? Do you have more open play or do you have heavy league and tournament lineage? Answering all of these will help narrow down which option will be best for your situation. Every center is unique, so as always, our Tech Support Team is available to guide you. You can also use the comparison chart below to help in your decision.

Now that you’ve got your new conditioner into your machine and ready to go, we always recommend running your normal pattern and watching ball reaction before adjusting anything. This way you’ll have an apples-to-apples comparison from conditioner to conditioner. It is highly likely, based on our experience with Fire and Ice, that pattern adjustments will be necessary.

To reap the benefits of these conditioners, your pattern should have good front to back taper. If you’re pattern doesn’t have good taper, our Tech Support Team can help you make some adjustments to maximize the performance of these conditioners. If you’re pattern does have good taper, some small adjustments may be all you need to dial in your pattern. Here are some of the common adjustments we’ve seen:

Reduced pattern volume (i.e. 50 ul to 45 ul or 40 ul)

Average pattern volume is 10-20% lower with Ice and 10-15% lower with Fire

Shortened pattern distance and/or reverse buffer drop

Reduction of applied loads

Don’t let the fear of upsetting your bowlers stop you from trying something new. You can reap the benefits of Fire and Ice with a little patience. Start now and you have the rest of the summer to fine-tune before fall leagues. You’ll enjoy the rewards of your hard work and patience when your bowlers are happy with the more durable lane conditions and you have less oil-related backend issues.

Learn more about Fire and Ice Lane Conditioners

What is "Waste" and Why You Should Care

What is “Waste?”

When most people hear the word “waste” they automatically think of chemicals or construction materials. And, they almost always think of waste as industrial and hazardous. Yet, the word waste is a very broad term that encompasses many different categories.

From your home to your bowling center, it is important to understand what waste is and how to dispose of it. With changing regulations, businesses that have been unaffected in the past, may soon learn the costs associated with improper disposal.

Residential Waste

First of all, everything that you put in your home trash can or recycle bin is considered a type of waste. Residential wastes can fall into a few different categories. Much of the waste we generate at home is recyclable. Think about the number of newspapers, magazines, cereal boxes (or other food boxes), soda cans, water bottles, and milk jugs that you use. Nearly all of those items can be recycled in some way. Recyclable wastes can be thought of as “good” waste. They cause little environmental impact and they don’t have any negative effects on humans.

But that isn’t the only kind of waste you generate in your home. Have you ever decided to paint a room? What happens to the extra paint when you’re finished with the job? You may keep it for some time but eventually it has to be discarded. Where does it go? Paints, bug sprays (pesticides), cleaning chemicals, and fertilizers are also examples of residential wastes. And, these wastes shouldn’t be thrown in your trash can. Many of these types of wastes must be disposed of more carefully as they can be hazardous to humans and the environment. In fact, many of these items are considered “household hazardous wastes”. Hazardous waste isn’t exclusive to industry; you probably have some of these types of items in your home right now.

These hazardous household wastes must be disposed of periodically and they can’t be just thrown in the trash. To assist residents in disposing of these materials, many local collection agencies arrange certain days of the week or month for residents to either put these types of items by the curb (similar to “everyday” trash) or to bring them to a designated drop off location for appropriate disposal. Items like used cooking oil and even electronics can be hazardous and should always be disposed of in a proper manner. Even light bulbs and batteries have special disposal requirements.

Commercial Waste

Businesses also generate waste. Some of the waste generated by businesses is just like the waste you generate in your home. Paper, soda cans, plastic bottles, and cardboard are all examples of wastes generated by businesses. These wastes, just like yours at home, can often be recycled and they would certainly be considered nonhazardous. But, businesses can also generate more dangerous or hazardous wastes. Hospitals and doctor’s offices have medical waste that must be disposed of properly to keep infectious diseases and germs from spreading. Industrial operations like chemical manufacturers, factories, and even construction sites all generate wastes that can be hazardous.

But, these businesses aren’t the only types that can generate such wastes. Businesses like the local bakery, the shoe store, and even the bowling center also generate waste. While these businesses may not generally create hazardous waste, they still generate waste that can’t always just go in the trash can or recycle bin.

Waste from Bowling Centers

A bowling center with a snack bar/restaurant can generate many different types of waste in each of its various operations. The snack bar/restaurant will generate food wastes, paper products and general trash, as well as wastewater from cleaning and used cooking oil from deep fryers. All of these wastes have different disposal requirements. The food waste and common trash items can generally be disposed of in a dumpster while the wastewater from cleaning; i.e. mop water, dishwashing liquids, etc.; can generally be flushed down the drain. Used cooking oil from deep fryers however, must be collected and disposed of according to specific regulations. In many cases, this material can be collected and recycled. And, in a lot of cases, the waste generator (the bowling center) may actually collect a fee from the recycler (the person who collects the waste for disposal and/or recycling). Many people would see this as a winning situation since they have to discard the cooking oil but they can make a little bit of money from the “waste” rather than having to pay someone to dispose of the oil.

The bowling center itself also has waste. Every time a lane machine moves down the lane to clean the lane and apply new lane conditioner, waste is created. The lane machine picks up a waste that is a blend of diluted lane cleaner, lane oil, and dust. Depending on the lane cleaner and lane conditioner used by the center, this waste is typically a large percentage of water. In fact, depending on the dilution ratio of the cleaner, the waste could be 90% or more water. Of the remaining percentage, a very small percentage; approximately 1%-2%; would be the lane conditioner while the rest would be lane cleaner.

The creation of this recovery tank waste is one of the most common waste questions I receive. When it comes to this waste material, everyone wants to know what to do with it and no one really wants to spend a lot of money to get rid of something that is mostly water. Unfortunately, as environmental regulations and waste disposal laws get tougher and tougher; many bowling centers are finding out the hard way that you can’t just dump this waste down the drain.

But, why can’t I just dump it down the drain? First, grease and oils are not soluble in water and tend to separate from the liquid solution. This means that when the solution travels through the pipes, the oil can settle and cause trouble; i.e. buildup which will ultimately lead to slow flow and clogging; in the piping. Secondly, oils also hamper the effective treatments that are performed at the wastewater treatment plants. In fact, it is because of this that grease traps and other type devices are required at some places.

Improper Waste Disposal

While the waste from the recovery tank of a lane machine would, in most cases, be considered nonhazardous, there are still appropriate disposal considerations that must be followed. And, to make matters even more difficult, the regulations vary by state, county, and city. Just knowing the federal regulations isn’t enough. Your state, county or city may have varying regulations so it is always important to check with the appropriate regulating authorities to determine your safest course of action. Improper waste disposal can carry hefty penalties as well as civil and criminal consequences. In fact, fines for improper disposal can be less expensive than the civil and criminal penalties imposed for the actions. And, the civil and/or criminal penalties could even include jail time!

As I mentioned previously, dumping your waste down the drain can cause problems with the sewage lines and at the wastewater treatment facility. But, it can also be traced back to the establishment as well. When sewage lines get plugged or have slow flow, maintenance workers have to clean the lines or even replace them. When this happens, the managing authorities can determine what caused the blockage. They can then pull samples from surrounding establishments to determine if the blockage was caused by one of them. By pulling samples from lines coming directly off of each of the surrounding establishments, typically, the managing authority can get at least trace amounts of the blocking materials allowing them to determine the offending establishment. They can then charge the establishment with a violation of the federal Clean Water Act. If this happens, the establishment may be required to pay for sewer line maintenance costs as well as additional water treatment costs.

Improper waste disposal can vary depending on the category of waste and the severity of the action. Improper disposal of hazardous waste would certainly be more severe and carry a harsher penalty than improper disposal of nonhazardous waste. That said imposed fines can be more than $30,000 per day! And that doesn’t even include civil or criminal penalties that could be imposed by a court. It also doesn’t include any additional treatment costs that may be imposed by the treatment facility or maintenance costs that may be required to replace or maintain sewage lines.

As I mentioned, the recovery tank waste will generally be considered nonhazardous. This is favorable as it is much less expensive to get rid of nonhazardous wastes than it is to dispose of hazardous wastes. Additionally, there are generally more options available for getting rid of nonhazardous wastes. This means you can shop around and find more cost effective alternatives which will save you some money on the bottom line. Generally speaking, depending on the number of lanes you have and the number of times you clean and condition your lanes per day, and depending on the regulations in your area, you could dispose of this waste for a few thousand dollars (or less) a year. When you start adding up the numbers for fines/penalties, it’s easy to see that the cost of appropriate disposal in one year would be far less than even one day of fines and penalties.

How to Properly Dispose of Waste

So now you’re probably wondering what you should be doing or even who to call that could help you get rid of this waste. As I mentioned before, regulations vary greatly by location so it’s extremely important that you find out what is appropriate for your area. You can always start with a call to your local waste management authority. They should be able to direct you to businesses in your area that can help you with your waste needs. You can also do an internet search for industrial waste or nonhazardous waste handlers. There are many companies around the world that can pick up and transport the waste to an appropriate facility for treatment or disposal. You can also call your local water treatment facility. They may be able to direct you to a company that can work with you. Lastly, if you use a service for a parts washer or even for oil disposal for your restaurant/snack bar, speak with your rep from those companies. They may be able to help you with this kind of waste or direct you to another company that can help you.

Waste disposal is becoming a part of operating a business and it is important, for humans and for the environment, that we dispose of all waste in the proper way. Businesses like bowling centers have generally flown under the radar. But, as regulations are becoming increasingly strict, there are increasing demands of wastewater treatment facilities, and the costs associated with treating wastewater and maintaining equipment increases, law makers and regulating authorities are taking a hard look at problems and where they are occurring. This means it is only a matter of time until your actions could come around to cost you. Taking the extra steps now to insure that you’re properly disposing of your waste may cost you a little bit of money now but it’s far less expensive than the fines and penalties you could be forced to pay, or the jail time you could serve, for improper disposal.