10 Frequently Asked Questions about Conditioning Lanes

Before making any adjustments to the conditioner pattern, make sure that your lane machine is cleaning properly.

Question: Ball reaction is weak after a game and a half. How do I reduce my carry down?

Answer: Typically the applied oil distance forward is too far creating too much conditioner towards the end of the oil pattern. Reduce the applied distance of conditioner and add to the reverse to prevent the loss of durability.

Question: Ball reaction is strong from the beginning and does not weaken making ball reaction unpredictable. How can I tame my back ends down?

Answer: First, try lengthening the pattern, one foot at a time to the desired result. Second is to change to higher speeds earlier in the pattern to raise the level of conditioner at the end of the pattern.

Question: The pattern plays good from the beginning yet loses hold through the night. How do I increase the hold?

Answer: The applied conditioner on the reverse is what creates durability, this area known as the mid-lane provides direction to the breakpoint and dictates score-ability. Starting reverse oil further down the lane increases hold.

Question: My bowler's tell me "the heads dried out". How do I control early hook?

Answer: First, watch ball reaction, bowlers rarely see what they think they see. In most cases the ball actually hooks too early through the mid-lane. Poor lane surface or lack of conditioner in the lay-down area can also be a cause. In this case, slowing the travel speed in the head area on the return will increase the amount of conditioner in this area. Adding loads in Sanction Technology along with a slower machine speed will increase skid through the heads. However, many times today with the amount of conditioner being applied to the "heads", if the ball is hooking early, there are lane surface issues.

Question: If I get the ball right, it "hangs" outside, 2,8,10 city! How do I create more room right?

Answer: This is a hard one to recognize, because it has multiple and opposite causes.

Too much conditioner on the outside (ball skids too far) or in some cases not enough conditioner on the outside (ball loses energy) can cause "hang".

If the ball skids to far, reducing the length and/or volume of the applied conditioner will help.

A wet/dry condition will result in too much skid inside, giving the appearance of "hang" and a loss of energy if the ball enters the dry too early creating a weaker back-end reaction. Many times the amount of conditioner in the middle is the cause of "hang" and not the amount on the outer boards. Reducing the amount of conditioner in the middle, raising the outside, and using speeds to lower the overall height of a pattern will increase ball reaction and create more playable angles.

Adverse lane topography can affect swing. If this is the issue, reducing the outside condition will allow bowlers to play a more direct line to the pocket.

Question: The bowlers seem to move left very quickly because the track dries up. What can I do to prevent this?

Answer: The volume at the end of the pattern should be slightly more than the outside boards. Applying oil to the track on the reverse can provide more durability without greatly affecting overall ball reaction. With Sanction Technology and board-by-board capability, widening loads one board at a time to get the desired affect can provide the quickest way and retain stability.

Question: How do I determine my cleaner ratio?

Answer: The best idea is to phone the manufacturer for their recommendation. All conditioners are different and clean off the lane differently. For example, Defense lane conditioner is usually stripped at a 4 or 5 to 1 ratio, while Offense can be cleaned at 8 or 10 to 1. This is something that you can experiment with, however, it is not recommended to weaken the stripping solution throughout the entire lane to control the back-end reaction. This can cause for poor cleaning and create numerous other issues.

(Note: With the FLEX lane machine, the ability to weaken the cleaner ratio mix ONLY on the back-end is an option to control back-end ball motion. The FLEX lane machine can keep a strong cleaner mix in the front part of the lane where it is needed.)

Question: How does temperature affect my lane conditioner and lane machine?

Answer: If you are using wick machines, it is highly recommended that you store the machine and conditioner in a place where it is room temperature and will remain constant. This will prevent inconsistent flow through the wicks due to changes in viscosity. In some conditioners, a 1-degree change in temperature can affect viscosity by 2 points cps. This is important for those with Sanction Technology to control the pressure and prevent possible damage to the gauge.

Question: Separate or Simultaneous?

Answer: This is an issue related to wick machines more so than Sanction Technology. Most centers try to reduce depletion one of two ways, either running in separate mode or stopping every so many lanes and letting the machine rest. The separate mode is recommended due to the consistent time in between the oil and strip mode. While the lane is being stripped, the wicks have that time to recover and it is the same from lane to lane. A major issue in resting the machine several times across the center is that it creates a stair step effect of gradually less, than more conditioner, repeated across the lanes.

Question: How does buffer brush wear affect my condition and what should be done upon installing a new one?

Answer: The buffer is designed to taper an oil pattern based off the pattern settings and speeds. As a buffer wears the amount of conditioner at the end of a pattern gradually diminishes over time. This is usually not something bowlers notice and will not come to your attention until you are told that you do not have "three units" any longer. Simply put the brush doesn't hold the conditioner as long as when new and "dumps" it further up lane and creates a steeper taper in the pattern. When replacing the buffer after this gradual wear and even though the pattern settings are the same as when the buffer was new, the effect of a new brush will seem dramatic to the average bowler.

It is highly recommended that this be done in August so the change is not taking place mid-season. The frequency of changing the brush is affected by many factors including number of lanes, how good the lane surface is, and what type of lane surface it is. The more friction the faster the wear. Smaller centers with 24 lanes or less may see two years between buffer changes. Centers with 24 lanes and up may change the brush every year to every six months in centers with a lot of lanes.

“The oil pattern didn’t play anything like it did at home!"

Often times I hear this comment and there are many reasons why this can happen. Frequently, the center that you are going to bowl the tournament in, say for example the USBC Open Championships, is using a different brand of cleaner, different oil, and a different lane surface, not even taking account of one of the biggest differences; topography.

Those are very obvious factors, but often people think that because they have the same lane machine as at the tournament site that it should cover all of those differences. Ultimately, even if you have the same lane surface, oil, cleaner, and lane machine, differences will still remain.

One of the differences we see often is the physical condition of the lane machine. Even though each Kegel lane machine leaves the factory meeting all of our strict adjustment and performance specifications, what happens to it from there is totally dependent on the maintenance (or lack thereof) that is given to it.

For an example, let’s compare two cars: Two 2011 Chevrolet Corvettes.

One Corvette lands in the hands of a business man who uses it strictly as a commuter car. He washes and waxes it every week, changes the oil right at 3000 miles, and always uses synthetic oil. He manages to put 25,000 miles on the car in a 12-month period.

The second Corvette ends up being a rental car. The car is in numerous drivers’ hands many of which perform routine burnouts and jackrabbit starts. This car also logs 25,000 miles in a 12-month span.

Though both of these cars started their life exactly the same, do you think both cars are going to look the same and perform the same after 12 months? Do you think the interiors are going to be the same? It wouldn’t surprise me if the rental car’s transmission doesn’t shift as crisp and probably a few of the basic items are a little more worn out (brakes, parking brake, tires, etc.) All I know is, I’ll take Corvette number 1 and you can take a chance with the rental car - haha!

Knowing this, do you think all lane machines are treated the same? We’ve seen many lane machines after one year look like they’ve never been cleaned! Oil drips out of the vacuum motor (where it never should), the transfer brush is filled with dirt and hair, the paint is peeling off due to cleaner being spilled on it numerous times, and the frame has been tweaked throwing the factory adjustments out of spec since the machine has been dropped more than a half-dozen times due to negligence.

Do you think that this machine I described above will put out the pattern the same way the brand new machines we have at the USBC Open Championships will?

Do you think the pattern will be the same with a machine that doesn’t clean the lane well because the squeegee blades or cushion roller have never been changed?

Do you think the pattern will be the same even if the cleaner tank filter is clogged and the Norprene cleaner tubing hasn’t been changed in over a year which results in half the amount of cleaner coming out (resulting in poor cleaning) and now you’re oiling on top of a film?

Do you think the pattern will be the same even if the transfer brush has so much dirt in it that it keeps the oil in the transfer brush an extra 6 feet down the lane?

Many factors will make a pattern play different from center to center but often one of the biggest is the physical condition of the machine itself. Stay up with the maintenance of the parts that commonly wear out; squeegee blades, buffer brush, cushion rollers, etc., keep the machine clean, and your lane condition will be more consistent from week-to-week and month-to-month.

Like our VP of R&D Mark Davis once said: “Machines that look like new, tend to perform like new.”

5 Must Know Things about Oil Pattern Taper

Oil pattern taper, the amount of lane conditioner in the front part of an oil pattern versus how much is at the end of the oil pattern, has had to change significantly as bowling ball technology has changed. Lane conditioner (lane oil) has two main functions; to protect the lane surface, and to provide smooth predictable ball motion for as many styles as possible.

1 - History

When bowling balls were balanced, the rotation of the bowling ball was very stable and there was essentially one oil ring on the surface of the ball. Front-to-back oil taper with balanced balls is very different than what is needed with modern high flaring balls, which have multiple oil rings on them.

Remember, with high flaring balls, the oil pattern breaks down from back to front and with low flaring balls it’s the opposite, oil patterns break down from front to back. As a refresher, here is an article on that explains how oil patterns breakdown differently between the two types of bowling balls: Breakdown and Carrydown – Then and Now.

At the same time that bowling balls were going through changes, lane surfaces were also changing – “it’s very hard to hit a moving target” was something John Davis used to say often when referring to the art of lane conditioning.

As we have shown often in seminars and online articles, regularly maintained wood bowling lanes are the most consistent type of lane surfaces from lane-to-lane, and bowling center to bowling center. There may be some lengthwise level differences from center to center, but the overwhelming majority of wood lanes were cut with a slight depression, which allowed statements like “the oil pattern taper should be 3:1” to be more valid.

With synthetic lanes however, lane shapes are all over the map, and blanket statements about front-to-back taper, or any oil pattern statement for that matter, can often do more harm than good for people trying to find the best solution for their bowling center.

In measuring hundreds of bowling centers around the world with the Kegel LaneMapper we have found the lanes in any one center follow the same trend as it relates to lengthwise levelness. The only exception to that rule is when bowling centers have added sections of lanes over time.

So if we simply talk about oil pattern taper as it relates to the lengthwise level of a bowling lane, if a lane went downhill we could easily increase the front-to-back taper ratio to help the ball slow down to achieve “good ball motion”. Conversely, if the lanes in a bowling center predominantly go uphill, we might decrease the taper of the oil pattern so the ball would slow down less in order to provide good ball motion for the majority of bowlers.

When lanes were made of wood and resurfaced often, and bowling balls were essentially balanced, it was that simple – but not today.

Today’s synthetic lanes can be crowned, they can be depressed, they can be depressed up front and crowned down lane or the opposite, they can be high right, high left, and anything in between. We very often have seen synthetic lanes that are shaped like a seagull wing; crowned outside and depressed in the middle.

Add the fact that your customers have bowling balls that are still balanced (low flaring) to the very unbalanced kind (high flaring), providing that perfect front-to-back taper can be a challenge.

Of course your daily house pattern is most important for your center, and getting that one pattern “right” can be accomplished, but applying a tournament pattern, or one of the many named patterns out there, and having players expecting it to play similar from center to center is like expecting to win the lottery.

2 - House Shot Patterns (Recreational Type)

Most daily patterns used in bowling centers around the world are of the easy variety – a lot of conditioner in the middle and not much outside. For these type oil patterns, it is most important to control the amount in the mid lane and at the very end of the pattern to 1, minimize carrydown and 2, to open up the outside portion of the lane.

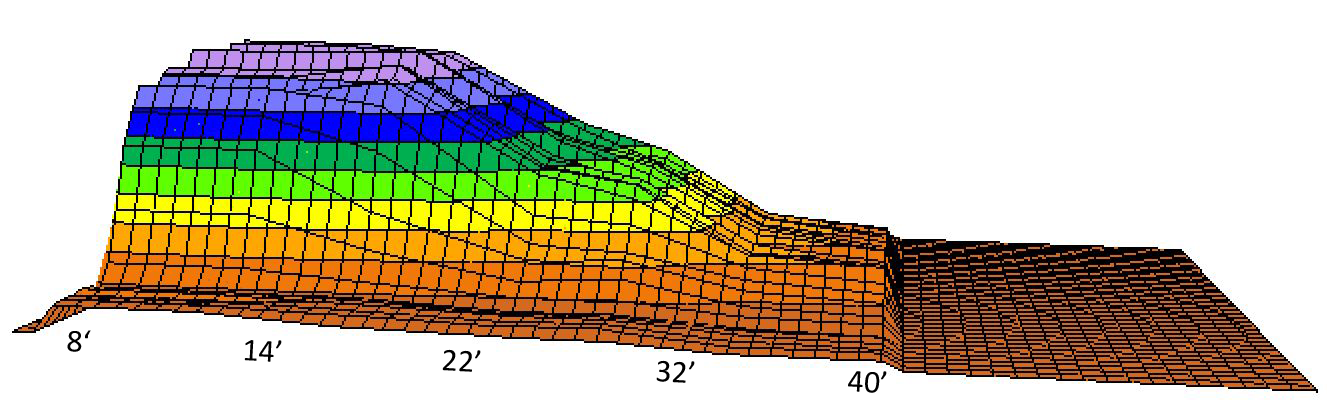

The graphic below is of a typical oil pattern taper when only non-flaring balls were in use. The goal then was to protect and apply conditioner only in the head area and let the conditioner “bleed off” the oil transfer system the rest of the way down the lane to the end of the oil pattern. From 8’ to the end of the pattern was typically a front-to-back taper ratio of 3-4 to 1 and that was with a maximum of 20 units in the head area!

Today’s oil patterns with today’s high flaring balls require a different type of taper, and much more volume. If we start with 80 plus units in the heads, there might still be 50 plus units in the middle to the 30 foot range. We do this in order to provide the bowler with a lot of hold area and decent ball motion, along with providing durability to protect the lane as long as possible.

To get that amount of oil throughout the pattern, the buffer brush must be loaded much more throughout the oil pattern with possibly a much more drastic drop off of conditioner towards the end part of the pattern. The amount towards the end of the pattern should decrease at a rate according to the type of lane conditioner in use and/or lane topography.

Below is an example of a typical daily oil pattern taper using high flaring bowling balls. As you can see, much more conditioner is used throughout the entire pattern.

The outside portion of the pattern has very little conditioner because most centers want to provide the bowler with a lot of mistake area outside of target. So even though we may want some taper there to allow the straighter player to start more to the right, most are concerned about not having too much conditioner towards the outside area in order to provide the largest margin for error possible.

3 - Challenge and Sport Oil Patterns (Competitive)

When designing competitive oil patterns, the goals of a specific oil pattern can vary greatly. If the pattern must play good on the fresh, because of a match-play format for example, finding that perfect taper for game one might be in order. That type pattern will usually be a higher front-to-back taper ratio in order to get the ball to read the lane sooner within the oil pattern.

If the goal is for the pattern to keep players in a specific zone for a longer time, front-to-back taper might not be as important as making sure the end of the pattern holds up for more games. That type of pattern would most likely have much less taper and play more difficult on the fresh, and then become easier as depletion towards the mid and end part of the oil pattern occurs.

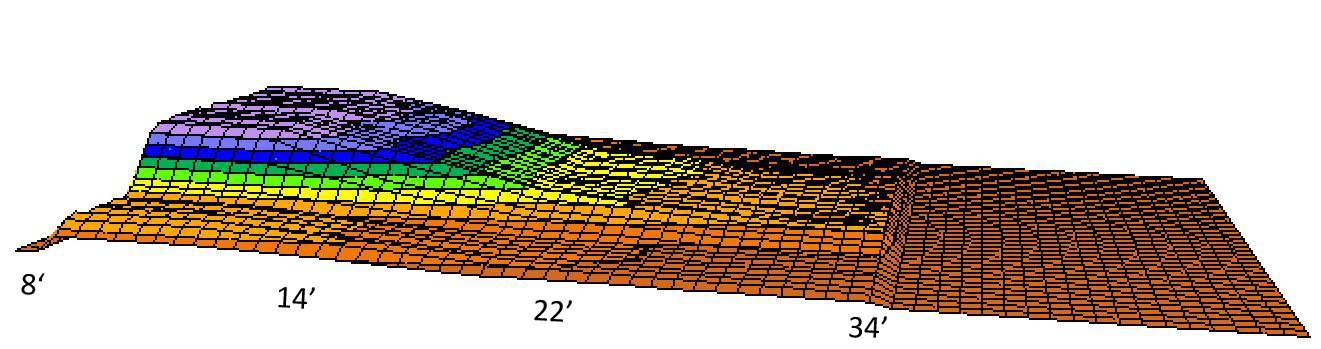

A perfect example of an oil pattern with very little front-to-back taper is the 2015 US Open pattern that was used in Garland Texas. The amount of oil in the middle at 8’ on this pattern proved to be in the high 50 unit range, at 22' in the mid 60 unit range, and at 2’ before the end of the oil pattern (41') was in the mid 30 unit range. The front-to-back taper in the middle of that oil pattern was about 1.75 to 1 from 8' to 41', and 2 to 1 from 22' to 41'.

Below are two graphics of the 2015 US Open oil pattern – the 3D and 2D graphs. Lane tapes were taken at 8, 14’, 22’, 27’, 32’, 36’, and 41’.

The pattern goal of that event was to try and keep the players from lofting the gutter, which was accomplished, but we cannot discount what was done with topography at that venue as well. Our studies show topography is always a factor in how oil pattern plays, develops, and breaks down. In this case, the USBC made topography public so we know lane topography definitely was an additional reason the pattern held up so well. (The why will be a future article!)

4 - Lane Conditioners

The lane conditioner you choose also must be factored into your oil pattern’s design. Lane conditioners are developed with specific characteristics and your oil pattern should complement those characteristics in order to benefit from them.

For instance; FIRE and ICE were created for increased durability and both require less conditioner at the very end of the pattern than many of our previous conditioners. If there is too much conditioner at the end of the oil pattern the ball will read the carrydown much more than if, for example, the same amount of Prodigy was at the end of the pattern.

If using our newest lane conditioner, Curve, more conditioner can be applied at the end of the oil pattern simply because it’s a higher friction conditioner, and that will help the ball slow down. Also, the ball won’t “see” what is carried down beyond the oil pattern as much as it would with FIRE or ICE. The trade-off however is durability.

5 - Topography

Now that we have those other factors covered, we can touch base on topography some more and how lane shape affects oil patterns. As we touched base earlier, wood lanes have very similar topography; all are slightly depressed (lower in the middle than the outsides) with the main differences from center to center in lengthwise levelness.

Yes we have more wear issues with wood lanes, which can be corrected with a resurfacing or re-coating, but with synthetic lanes we have more diverse shapes on the lane than ever before in the modern history of the game. Those shapes can vary from lane to lane, and even within the same lane. This makes finding that perfect oil pattern on synthetic lanes across any one bowling center more challenging than ever.

For lanes that are predominantly crowned, lowering the amount of conditioner in the mid lane and at the end of the pattern will help the ball lose energy at the proper rate, which will help provide truer ball motion. Crown lanes tend to act like lanes that go downhill, so anything you can do to help the ball slow down will help your bowlers with good ball motion.

For lanes that are severely depressed, and if you wish your bowlers to play right of center, additional conditioner in the mid lane and at the end of the oil pattern helps reduce friction slightly, and therefore helps the ball not lose energy as quick. Think of depressed lane like a banked curve on a race track – the inside part of the lane is lower than the outside part of the lane so the ball is rotating up the hill causing it to use energy quicker, along with normal force helping the ball move more to center.

For seagull wing shaped lanes, and believe us when we say there are many overlays like this, shorter patterns will need increased front-to-back taper in order to get the ball to read the lane earlier. Yet longer patterns on this lane shape will need less taper simply because from 10-10 the lane is depressed - once the ball gets towards the middle and end part of the pattern it sees the lane more, and sooner, as the oil depletes.

Conclusion

In the article titled Breakdown and Carrydown - By The Numbers, we showed how today the front part of the lane never really depletes to the point of excessive friction unless there is a major wear issue – it’s the mid lane and backend that deplete to the point of the ball seeing a great amount of friction.

Sure the front part of the pattern depletes, but if we start with 70-100 units up front, or less like in the US Open example, at the end of play there is still 30 to 40 plus units of conditioner in the front part of the lane, which is plenty to provide a low amount of friction.

In addition, that part of the lane the bowling ball has the least amount revolutions and the most amount of speed - both of those attributes make the ball “see the lane less” than it does at it slows down and revolutions increase.

The point is, front-to-back taper ratios with today’s patterns is not as important as controlling the amount of conditioner in the mid lane and at very end of the pattern.

If you get that correct in your center, the majority of bowlers in your center will have predictable and controllable ball motion, and back end change (carry down) will be minimal. And for the most part, hopefully, you will have happy bowlers.

The Truth About Tournament Oil Patterns and Conversions

At Kegel we get many requests for converting oil patterns to and from different lane machine technologies. Sometimes it can be for a specific tournament pattern or it may be a named oil pattern. Although we fully realize the intent, we also know that there are many factors other than the oil pattern that determine ball motion, and how easy or difficult lanes play.

One technical reason some oil patterns cannot be converted is simply because some lane machines do not have the capability to apply an oil pattern exactly like the machine it was made for. A few of the new longer Landmark Patterns are good examples as these patterns were designed specifically for the FLEX lane machine.

For example, the Eiffel Tower is a 48 foot Sport pattern and with the variable buffer speed upgrade feature the FLEX has, the last seven feet utilizes a buffer speed of 200 rpm which applies a very light film of conditioner in this zone. If a lane machine does not have the variable buff option the buffer will be rotating at 500 rpm, and apply more conditioner to that zone, making the pattern play much tighter that it was intended to play. That doesn’t mean you can’t have fun if applied with other lane machine technology or the pattern will be terrible, it just won’t “play the same”.

However, even if the oil pattern is matched up perfectly from one technology to the next, there can still be differences in types of conditioners used, cleaner type, cleaner dilution, lane surface friction, and lane surface topography. Even bowler differences (who you will follow at the tournament) from your home center to wherever that tournament pattern will be used at can have a huge impact.

For instance, some lane conditioners play slicker or allow the ball to pick up earlier than other conditioners, some conditioner’s carrydown affect ball motion more than other conditioners, and some lane cleaners leave more residue behind than others causing different amounts of back-end hook. The dilution ratio, the amount of cleaner to water mixture, also affects ball motion, especially at the back-end.

For lane surfaces, conditioned wood lanes tend to hook more and earlier than conditioned synthetic lanes. Higher textured synthetic lanes tend to have an “arcing” ball motion, while smoother synthetic lanes tend to be more “skid-snappy”.

When practicing on a tournament pattern at home, you may be all alone or with a small group with similar styles. We know in today’s bowling environment using today’s equipment, it doesn’t take very long to change that oil pattern into something else simply by rolling balls down the lane. Once at the tournament site however you will be following a much more diverse group of styles, which may very well transform that oil pattern into something different.

It’s not even uncommon for us to see the scoring pace change from different squads in the same tournament using the exact same oil pattern just by the style of bowlers on specific squads, or even by the type of bowling balls used by the participants on different squads!

Topography is also a huge variable when it comes to how a ball hooks (how a ball depletes energy) and how much it hooks. A portion of a lane sloped opposite the rotation of the ball will cause the ball to lose energy quickly, while a portion of a lane sloped with the rotation of the ball will cause the ball to lose energy slower. These slopes on the lane surface can also help the ball move more easily towards the pocket, or make it more difficult for the ball to move towards the pocket.

A textbook example of how lane surface and topography can affect scoring pace is from the 2014 and 2015 Teen Masters. In this event, many of the participants played both years, all players use the same type balls, the same oil and cleaner were used, and the long oil pattern was exactly the same both years, so we can discount all those variables.

However, in 2015, the event was held at a newer installation and the lanes are predominately shaped with a certain type topography that is known to produce high scores; the overall scoring pace was 20 pins higher in 2015 than in 2014 and an abnormal amount of 300 games were bowled. The 2015 environment also benefited some players more than others as averages between the two events were 40 pins higher per game in 2015 versus 2014, for certain styles of play.

Kegel has mapped thousands of bowling lanes around the world and we have yet to find two lanes that have the exact same measurements with regard to lengthwise tilts, crosstilts, crowns, and depressions. We also have yet to find a perfectly level lane. It could be said that bowling lanes are like finger prints; no two are the same.

Therefore, perfect and exact pattern oil patterns, or conversions, GUARANTEE that ball motion will be different at home versus where you will play on that pattern at whatever event you are going to.

A good coaching tip is to practice on a competitive type oil pattern that has a similar distance to the tournament pattern you will be bowling on. This type of preparation will help you to keep an open mind and to be flexible when you arrive at the tournament site. It is easy to get overly caught up in oil patterns with all the information and focus on oil patterns today. Unfortunately, more often than not, this closes the mind and shifts focus to “what should be” instead of “what might be”.

In conclusion, if you are practicing at home on a tournament oil pattern, and planning on competing or coaching in that tournament, take that oil pattern with a grain of salt and keep your mind open - very open. We can just about guarantee things will be different at the tournament site than at your home center.

2015 USBC Open Championship Oil Pattern Program Sheet

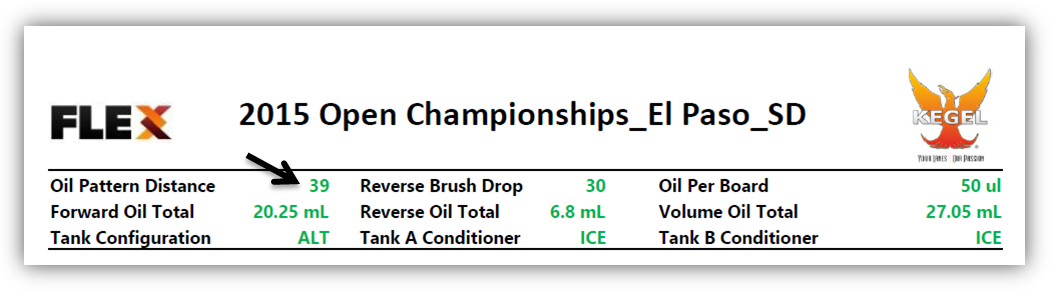

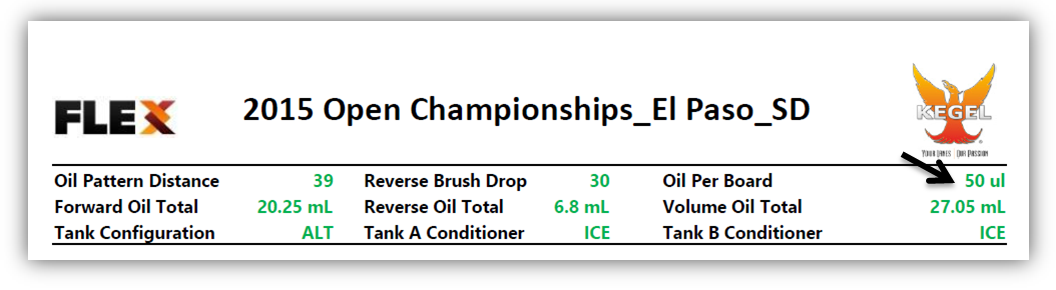

This month’s Inside Line feature article is about key items on the KEGEL FLEX program sheet of both the Team event and the Singles and Doubles event oil patterns for 2015 USBC Open Championships.

Oil Pattern Distance

Oil pattern distance is one of the main key items to look for on any program sheet. The distance tells us how much dry back-end area is within any one pattern and can give us a good idea of where to play on the lane, providing the lane surface is fairly neutral. Essentially, the shorter the oil pattern is, the farther towards the outside portion of the lane one should play, and the longer the oil pattern is, the farther inside a pattern might play. Of course there are other variables that can affect this theory; like the amount of conditioner on the outside portion of the lane, the shape (topography) of the lane surface, and the friction of the lane surface. However, knowing the distance of the oil pattern, and how it affects your particular style of play, can help you line up quicker than not knowing this important pattern detail.

The distance of the oil pattern can be found at the top left corner of the KEGEL FLEX program sheet.

Oil Per Board Value Number

The Oil Per Board value, found at the top right of the FLEX oil pattern program sheet, is the size of the oil stream in microliters - the higher the value, the larger the oil stream, and the larger the stream, the more conditioner is applied to the lane.

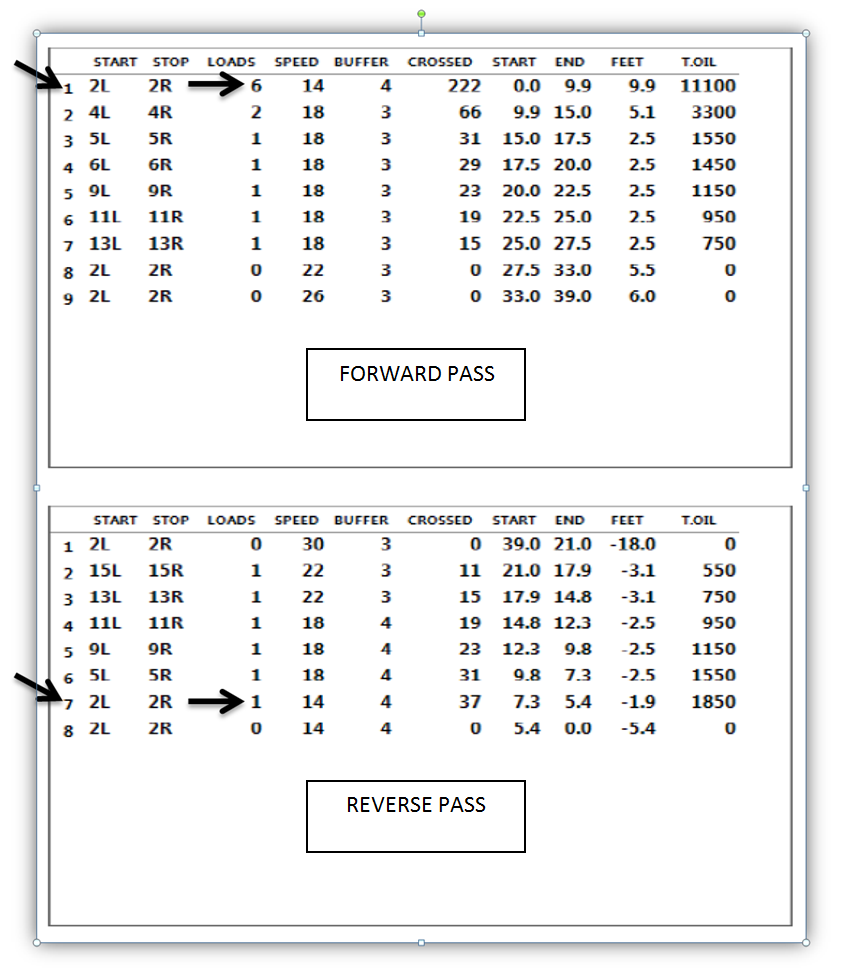

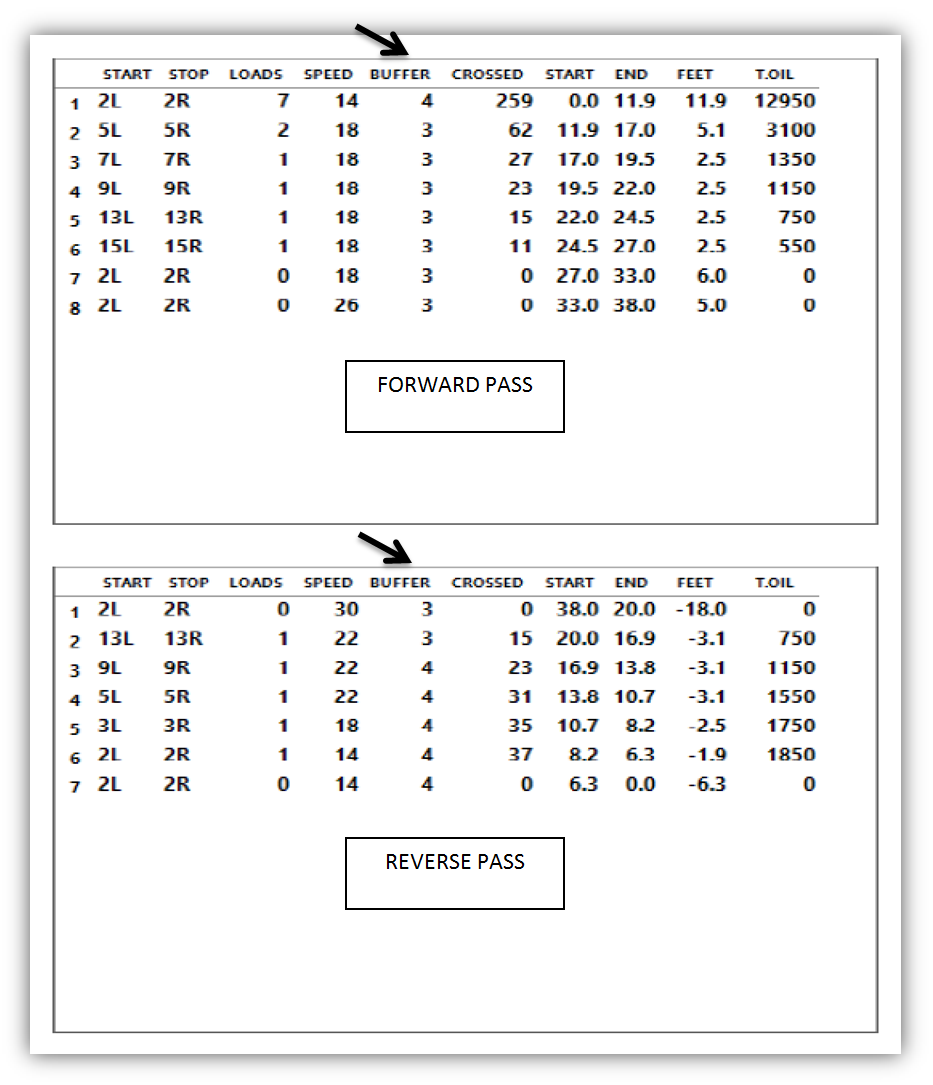

Number of 2-2 Loads

The Number of 2-2 loads can often be a measure of difficulty. Think about these loads as the base of the oil pattern and all loads inside of the 2-2 loads are the shape of the oil pattern. The more 2-2 loads the more difficult an oil pattern will play because once there is a certain amount of conditioner across the entire lane surface, the shape of the oil pattern becomes less relevant.

At this year’s Open Championships, the 2-2 loads make up 12.95 milliliters of the total volume of the 27.05 singles/doubles oil pattern and 14.80 milliliters of the total volume of the 26.90 milliliters team event pattern. In comparison, in most house patterns the 2-2 loads make up 3.7 milliliters of the total volume of the pattern which is in the 22 milliliter range.

The 2-2 loads are normally the first loads on the forward pass and the last load before the buff line in the reverse pass.

Buffer RPM

The FLEX lane machines in use at this year’s championship have four buffer speed options, which are noted on the program sheet by the numbers 1, 2, 3, and 4. Number 1 is what we call slow buff, and it has a speed of 100 RPM. Number 2 is medium buff and has a speed of 200 RPM. Number 3 buffs at 500 RPM and is the default speed that is used on previous models such as the Kustodian ION and Kustodian Walker. Number 4 is high buff and has a speed of 720 RPM. (Note: Individual FLEX owners can customize the buffer RPM settings for their needs, so you may see different numbers on different program sheets.)

The different buffer speeds on the FLEX allow us to do a couple things; one is it allows us to fine tune the front to back taper of the oil pattern without changing lane machine drive speeds. The other is it allows us to condition the lanes in less time by allowing us to apply more conditioner in the front part of the lane without slowing the machine down, as we would have to do in machines with single speed buffer motors.

In short, the faster the speed of the buffer brush, the more conditioner can be applied in any one section of the oil pattern. Conversely, the slower the speed of the buffer brush, less conditioner will be applied to the lane surface.

You will notice on this year’s championship patterns the choice of using buffer speed 4 in the front part of the oil pattern on both the forward and reverse pass of the pattern. Medium and slow buff is not used in this year’s patterns.

The Load Structure

As previously mentioned, once there is a certain amount of conditioner on the lane the load structure becomes less relevant. However, one thing to note this year compared to recent years, and a house pattern, is how none of the loads are “stacked up”. This means the inside load streams are spread out across the oil pattern which makes the pattern a simple blend, or crowned oil pattern (See graphics above).

Because of this type load structure there is not a defined oil line anywhere throughout either the Team or Doubles/Singles event patterns which places a premium on consistent shot making and accuracy. Only once bowling begins, and depletion takes place, can an oil line be developed if, and that is a big if, everyone plays in the same place from the beginning of practice to at least through the first few frames of game one. This is called “managing the oil pattern” in modern bowling vernacular.

This year’s USBC Open Championship should prove out to be one of the lower scoring championships in recent years simply because of the flatness of the patterns. However, it should also prove out to be one of the most competitive because when scores are lower, the gap between the higher scores and lower scores is much narrower.

In closing, if you have not already made the trip to El Paso, practice your spare game, have a good game plan with your teammates, and let your ball be your guide.

Who do you follow? We're not talking about Twitter...

In previous Inside Line articles, we showed how oil pattern breakdown happens with today's high flaring bowling balls and how different styles of play can affect an oil pattern in different ways. In this article, we will show how different groups of players with similar styles can greatly affect an oil pattern by strategically "managing the oil pattern" during practice time and the first game, and the resulting scoring pace for all those that follow these skillful "pattern managers."

The scene was the Men's Team event second block on the WTBA Seoul oil pattern during the 2013 WTBA World Championships in Las Vegas. The WTBA rule for practice time for 5 person team event is 15 minutes, then all teams bowl 3 games moving lanes every game. This gives us about 4-5 games per lane by the time each team finishes the 3rd frame of game one.

Our testing and after tapes at many modern day events show that when players play a similar line each and every shot during this time on a fresh oil pattern, over 50 percent of the lane conditioner can be removed from that area throughout the ENTIRE length of the applied oil pattern. This is significant and something all competitive players and coaches must be aware of in today's game.

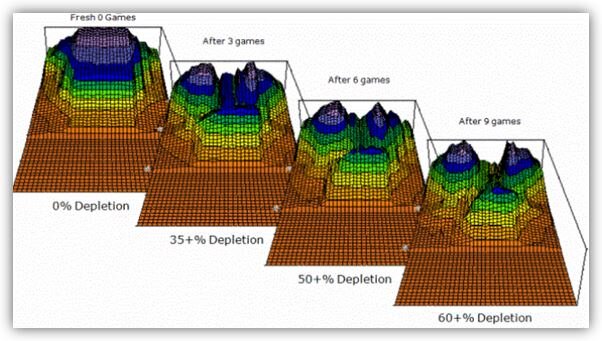

Here was a test showing how much conditioner was removed in the area of play after each 3 games:

The significance and rapid pattern change is so prevalent in today's game that some Federations even employ multiple coaches during championships- one coach on the lanes helping the players during competition, and another coach "scouting out" the pair of lanes they will be moving to. Just knowing how and where the teams are playing on the lanes in front them can give them valuable information and help them get lined up quicker. In championship events, this can be the difference between winning, losing, or not even getting a chance to win. This played out exactly this way during the 2013 World Championships this year in the men's division.

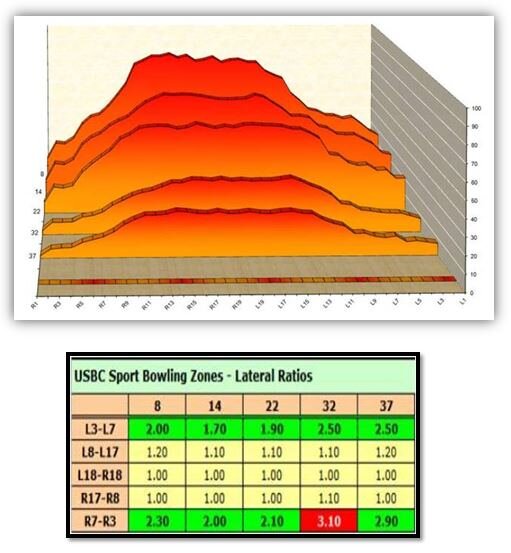

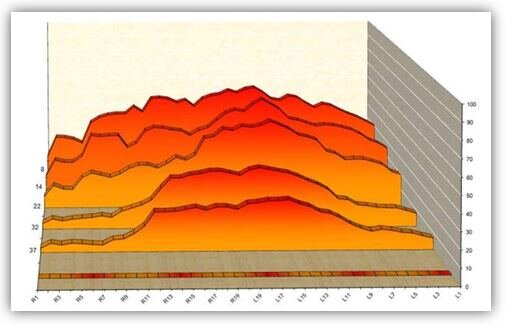

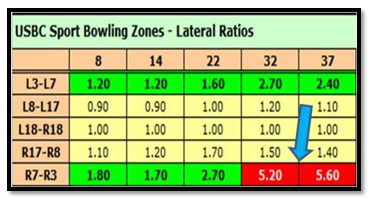

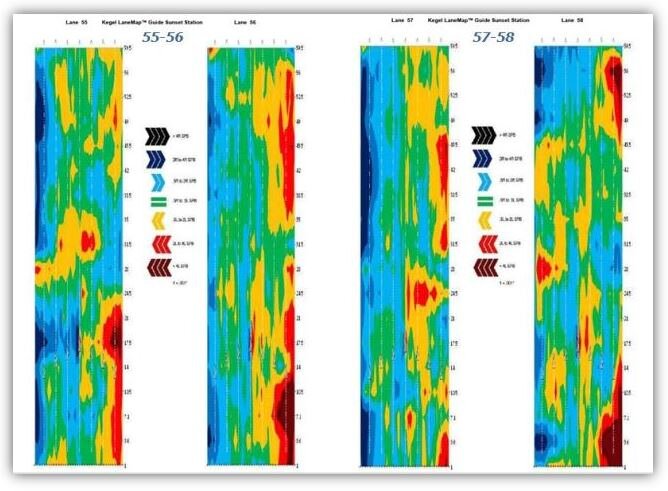

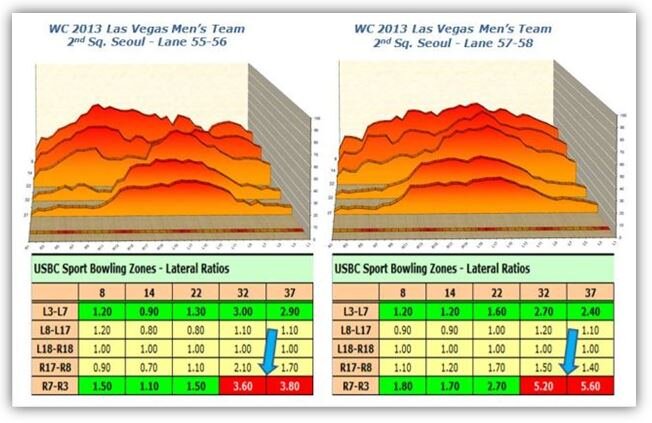

Here is a graphic of the Seoul oil pattern just before the men's second squad of team event took the lanes - the graphic is with the perspective of looking at the oil pattern from the pins, so the 10 pin side is the left side of the graphic. Also shown below are the Sport Bowling ratios at multiple tape distances before the players took to the lanes:

As a side note, the WTBA Seoul oil pattern is asymmetrical with more oil outside on the left side than the right side, hence the lower ratios on the left side. You may also notice that at 32' this pattern does not fall within the 3 to 1 ratio parameters, but Sport Bowling ratios only use 22' and 2' before the end of the pattern to calculate whether it meets USBC Sport Bowling requirements, and the WTBA does not have any ratio requirements.

During this second block of team play, with these pairs of lanes being right in front of the tournament office, I was able to watch and see how each of the teams on these pairs were breaking down the lanes during the 15 minutes of practice. While watching Puerto Rico and Brazil on 57-58 play more outside, and the teams on 55-56 play more inside, I was wondering how much an effect that might have on the teams coming to these pair of lanes in games 2 and 3, so I planned on taking after tapes as soon as the block was over. Little did I know at the time, the way the teams on 57-58 broke down that pair would help Team Finland make history.

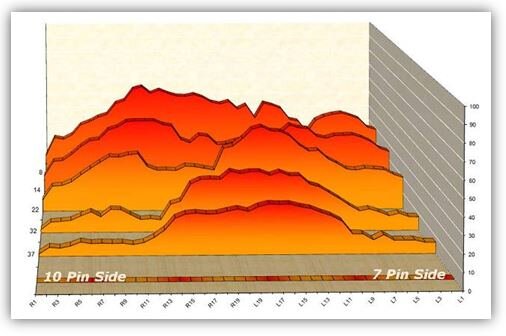

After 15 minutes of practice and three 5-man team games (15 plus games per lane), here is what the Seoul pattern morphed into on lanes 55-56:

From looking at these after tapes, it is clear how deep inside the bowlers on this pair ended up playing the lanes, which all came from how the initial teams decided to play the lanes in practice and game 1.

Here are the after ratios of lanes 55-56, calculated the same way as before:

The ratios normally get lower up front as the oil pattern gets depleted from the middle of the lane. What makes scoring pace rise as players break down the oil pattern is when all balls come together towards the end part of the oil pattern, which raises the ratios from outside to the middle. In this example the ratios from the fresh oil pattern went from about 3:1 to 3.6:1 at 32 feet and from 2.9:1 to 3.8:1 at 37 feet. This is enough for world class players to increase the scoring pace, and this block was no exception.

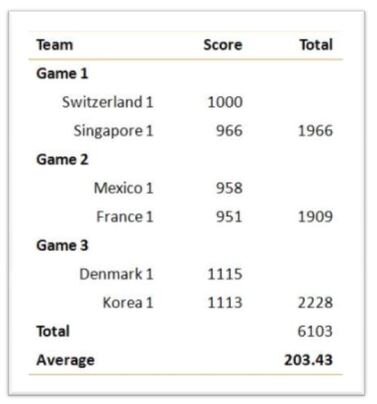

Here is the resulting scoring pace of each team for each game of this particular block of games on lanes 55-56::

As you can see by game 3 that pair became more playable because of oil pattern development with both Team Denmark and Team Korea breaking the 1100 barrier. It took longer because of how deep the previous teams played that pair. The reason it took longer is because when teams start in the deeper amount of oil, it takes longer for the ball to reach the "spark point", or in other words, break down the oil pattern enough for the ball to poke through the oil film and get to the lane surface. Once the ball sees the lane surface, it also sees friction. The earlier the ball sees friction within the oil pattern, the easier that pattern becomes because left of that is the created oil line.

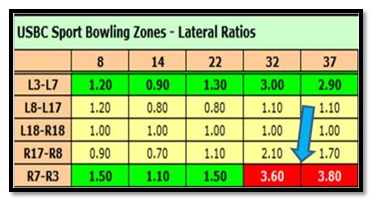

And now the pair of lanes where the Seoul pattern was changed into something else, which helped Team Finland make history. The mutated Seoul oil pattern on lanes 57-58:

From looking at these after tapes, it is clear how much more outside the bowlers on this pair ended up playing the lanes, which also was decided because of how the initial teams decided to play the lanes in practice and game 1.

Here are the after ratios of this pair, calculated the same way as before:

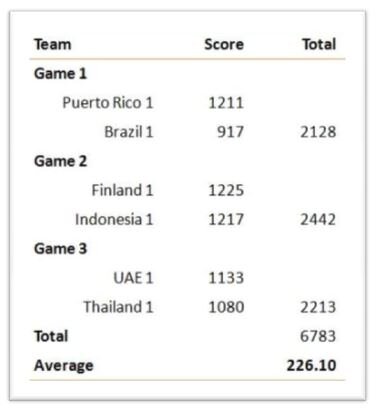

While lanes 55-56 went to 3.6 and 3.8 to 1 towards the end of the oil pattern, the players on lanes 57-58 took the ratios to 5.2 and 5.6 to 1! This is borderline what many house shots are in today's game, but like I said before, most of the change happens within practice and the beginning of game one.

Here is the resulting scoring pace on lanes 57-58 of each team for each game during this block of games:

As you can see by the team game total scores, the teams that were fortunate enough to follow Puerto Rico and Brazil benefited greatly, but none more than Team Finland. This second team game with a score of 1225, along with the momentum that gave them and another 1200 plus score in game 3, catapulted them into the Team finals. After winning their semi-final match they defeated Team USA in the finals for the first team Gold medal for Finland in 30 years.

Fortunately, during this championship we also had available Kegel's LaneMap Guide of Sunset Station which shows the gravity influence on the ball based upon topography so we were able to see if one pair was significantly different causing that to be the reason for higher scores this block on 57-58, but that proved to be not the case, as the below graphic will clearly show. Both pairs have very similar characteristics.

Finally, one more look an after bowling graphic of both patterns and the resulting ratios side by side:

A well renowned Kegel laneman and now National Team Coach for Indonesia, John Forst, had a saying; "the applied oil pattern is only the pattern until the bowlers start bowling on it. After that, they are the ones that decide what happens, not the laneman."

In today's vernacular, the Seoul oil pattern, or any other named oil pattern for that matter, is only the intended pattern until players start rolling balls over it, and then that named pattern becomes something else. Some players can turn it into Easy Street, and some can turn it into the Highway to Hell. Keep your fingers crossed you follow players that can turn things into Easy Street.

Oil Pattern Graphs: KOSI Composite Graphs

How many times have you gone to a bowling tournament, or even a bowling league, and seen a lane pattern graph and not known what in the world you were looking at? I was at a collegiate bowling tournament where lane graphs were given to the teams at check-in and I heard many a team trying to decipher what the lane graphs meant. Over and over, I heard teams trying to decide where to play based on the lane graph. It actually surprised me how many people didn’t know what to look for.

If you are like me, and I know there are many of you out there, when you look at a lane pattern graph, you don’t really know how to extract information from it. Basically, you’re just looking at a picture of a lane or worse, some lane tapes that might as well be written in an ancient language. To help you, I have consulted some of the top minds in pattern theory for a little lesson in how to read and understand the various types of lane graphs.

To begin, we must first understand that there are different types of lane graphs. Some are related to the lane machine program sheet and some are related to the actual oil pattern on the lane.

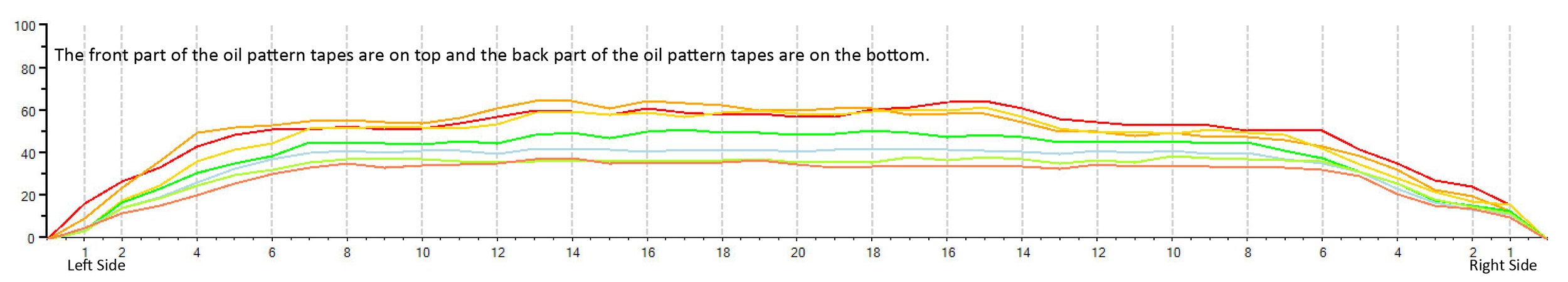

Calculated from the lane machine settings (the program that is entered into the lane machine), we have the overhead graph and the composite graph. From lane tape readings (taken directly off the lane from the oil itself), we might see the 3D graph or the 2D graph. Each of these graphs look different and provide different ‘views’ of the oil pattern, but ultimately they all give you the same basic information – the shape of the oil pattern.

Some of the information you should look for, regardless of the graph type, is pattern distance, pattern volume, inside/outside ratios (don’t get confused, we’ll discuss) and pattern shape. All of these things will provide clues about what to expect from the oil pattern.

Pattern distance tells you how long (or short) the lane pattern is; in other words, how far down the lane from the foul line the oil is applied. A short pattern will play much different than a long pattern simply because there is longer part of the dry lane to deal with.

Pattern volume tells you how much total oil is applied to the lane. It does not tell you where that volume is; only how much oil is there. The total volume of oil is measured in milliliters and per board values are measured in microliters.

When you see a graph with units as the value, it is a calculated measurement based upon the ultra violet additive (UV) that is mandated to be in each batch of lane oil. The UV additive allows the optical lane reader to “see” the oil. Units of oil should not be confused with volume of oil.

Ratios tell you the difference in the amount of oil from left to center and right to center. Pattern shape is the shape of the oil on the lane. Some examples of shape are top hat, block, Christmas tree, or flat.

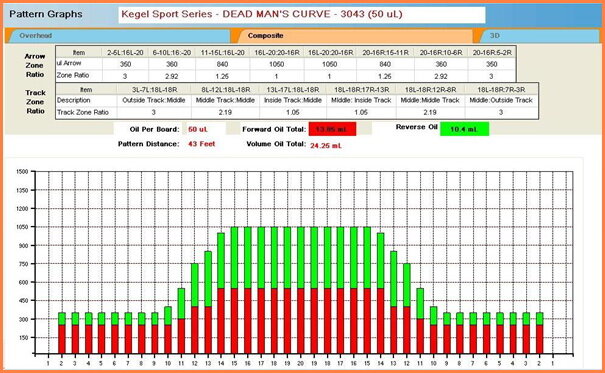

The first type of graph we’ll study, the composite graph, is one that most people will see most often. The composite graph is also called a volume per board chart. The composite graph, shown below, gives us the total amount of forward and reverse oil that is applied to the lane. The total amount of applied oil is calculated based on the program that is entered into the lane machine.

In actuality, the composite graph shows us the amount of oil on each board. The best way to understand the composite graph is to imagine taking all of the oil that was applied to the lane, then drag it back to the foul line and stack it up. This would look like the composite graph.

Take a look at the composite graph example below.

Along the bottom, or the ‘x’ axis for you math people, you can see the lane boards labeled; board one on the left to 20 in the center to the one board on the right.

Along the side, or the ‘y’ axis, the amount of oil is measured in micro liters.

This particular example is the composite graph for Dead Man’s Curve, a Sport pattern in the Kegel Navigation Series. Sport Bowling uses ratios to describe (or define) the level of difficulty of a pattern; a lower ratio is more difficult than a higher ratio. The Sport Bowling ratio is defined as the average amount of oil (in units) between boards Left 18 to Right 18 divided by the average amount of oil (in units) between boards R3-R7 & L3-L7, respectively.

While this graph does NOT give us units, nor does it tell us exactly where the ratios are within the oil pattern, it is still a good reference. In this graph, we can see that there is about three times as much conditioner in the middle of program as there is on the left and right side of the program; a 3 to 1 ratio.

The chart area above the graph, which you may or may not see on a composite graph as it depends on how the graph was generated (which computer software program generated the graph), also gives information on ratios in different parts of the pattern program. It may be somewhat difficult to read in this example due to the size of the picture; however, some information about ratios around the track area is given.

The track area is generally defined around the 10-board on either side of the lane (typically a bowler will play the track on a house shot). In this example, ratios are given for outside the track (boards 3-7 on either side of the lane), middle track (boards 8-12 on either side) and inside track (boards 13-17 on either side). In general, the lower the ratio of the oil, the more difficult the pattern will be to play.

In this example, the inside track (boards 13-17) would be very difficult as it is basically flat with a 1:1 ratio whereas the outside track (boards 3-7) would be somewhat easier at a 3:1 ratio. To put the ratios into perspective, a house pattern might be 6:1 or even higher. A high ratio program, like many house patterns are, will give the bowler a defined “ridge” to play against within the oil pattern.

This difference can help you determine how best to play the lane. Don’t misconstrue that; the composite graph can give you an idea of how to play the lane, but a common misconception is that it can tell you where to play the lane. This isn’t always true since the topography of the lane surface can often be more dominant than the oil pattern.

The composite graph is more of an idea of how difficult, or how easy, the oil pattern may play. Again, generally the lower the ratio of conditioner from the inside to the outside, or the flatter the oil pattern, the more challenging the oil pattern will be.

The last things to note in this graph, and they may be difficult to read because of the graph size, are the pattern distance and pattern volume. In this particular example, the pattern distance is 43 feet and the total volume is 24.25 mL.

Since a lane is 60 feet from foul line to head pin, there is 17 feet of ‘dry lane’ after our 43 foot Dead Man’s Curve pattern. That basically means there is 17 feet of friction that the ball must move through before it hits the pins.

We hope this information has helped you understand how to read a Composite Graph. It is important to remember that the information is only as useful as your interpretation. The graph isn’t telling you where to play; it is only providing you with some information to help you make an informed decision regarding lane play.

Next time, we’ll see another type of graph, learn about how to read it, and extract useful information from it. Until then, Happy Bowling!

Breakdown and Carrydown - By The Numbers

In our last Inside Line feature article, Breakdown and Carrydown – Then and Now, we discussed the reasons why breakdown and carrydown are different today. For this edition’s feature article, we will add some data and visuals to support the previous article. The data was taken from the recently concluded European Bowling Tour Masters in Munich, Germany and it shows the same thing we often see in bowling tournaments today.

The event consisted of the top 16 men and women from the 2011 European Bowling Tour point list. On the men’s side there was a mix of styles; high rev players, medium rev players, and low rev players, with fourteen right-handed players and two left-handed players. On the women’s side there was also a good mix of styles, even though most fall into the medium to low rev rate category, with 15 right-handed players and one left-handed player.

The players on the men’s side were: Martin Larsen (RH), Mika Koivuniemi (RH), Karl Wahlgren (RH), Sean Rash (RH), Gery Verbruggen (LH), Dominic Barrett (RH), Perttu Jussila (RH), Syafiq Ridhwan (RH), Osku Palermaa (RH), Mik Stampe (RH), Paul Moor (LH), Dennis Eklund (RH), Jesper Agerbo (RH), Robert Andersson (RH), Thomas Larsen (RH), and Stuart Williams (RH).

The players on the women’s side were: Rebecka Larsen (RH), Clara Guerrero (RH), Mai Ginge Jensen (RH), Krista Pöllänen (RH), Nina Flack (RH), Patricia Luoto (RH), Wendy Kok (RH), Bianca Wiekeraad (LH), Britt Brøndsted (RH), Joline Persson-Planefors (RH), Jacqueline Sijore (RH), Zandra Aziela (RH), Lisanne Breeschoten (RH), Nicole Sanders (LH), Heidi Thorstensen (RH), Sascha Wedel (RH).

The Data and Graphics - Breakdown

The oil pattern used for the event was Kegel’s Navigation Sport Series pattern The Turnpike. This pattern is almost flat from the midlane to the end of the pattern because the forward application consists of only 2L-2R loads. The shape from the mid portion of the oil pattern to the foul line is built on the return pass.

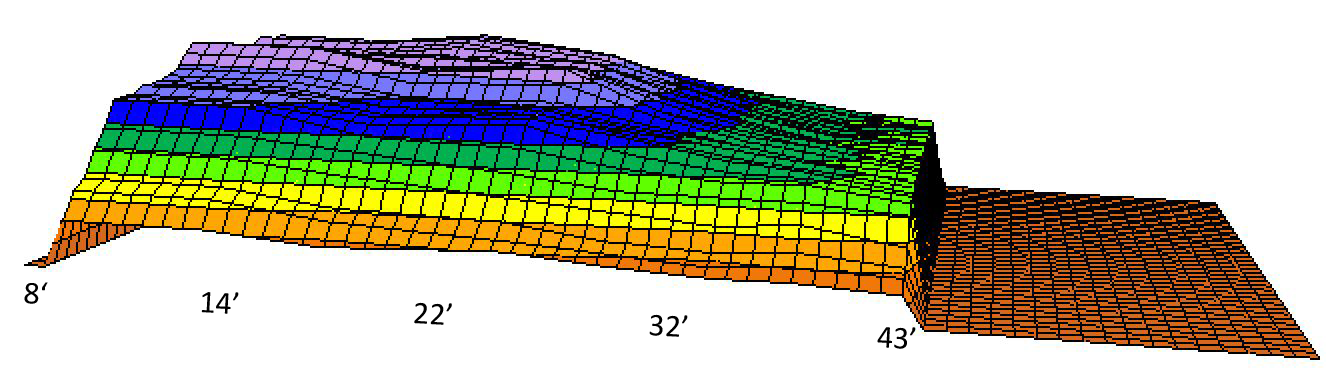

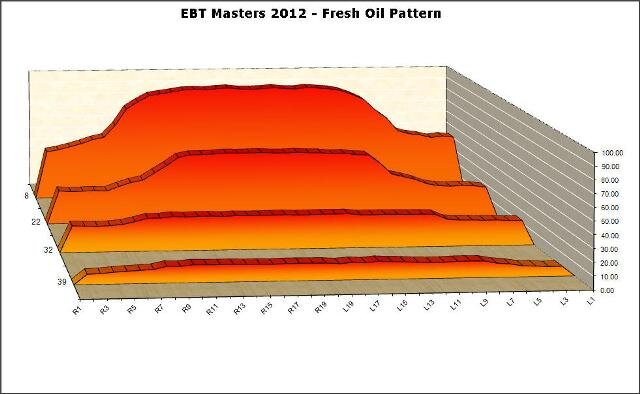

Here is a graphic of the fresh oil pattern with tapes taken at 8’, 22’, 32’ and 39’ (left side of the graphic is the right side of lane, right side of graphic is left side of lane – you are looking at these graphs from the pins perspective):

As we have known for many years, apart from the type of equipment being used, how the oil pattern breaks down is dependent on where the players play on the lane. When styles or rev rates are more similar, players tend to play in a more similar area of the lane, causing a much different type of pattern breakdown than when styles and rev rates are more diverse.

During the EBT Masters, all blocks consisted of 6 games with four players per pair, which equals 12 games per lane, plus ten minutes of practice. In comparison, a five person league would be 15 games per lane, plus 10 minutes of practice.

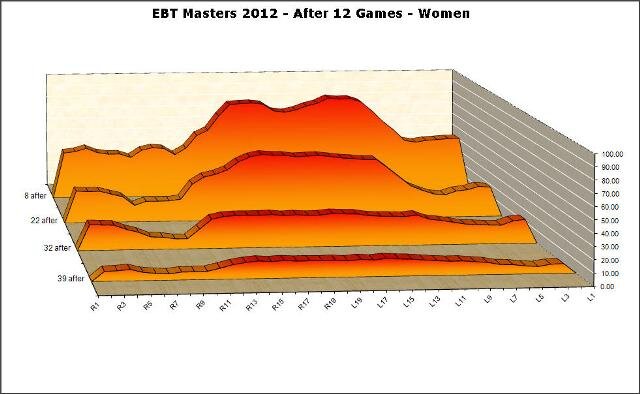

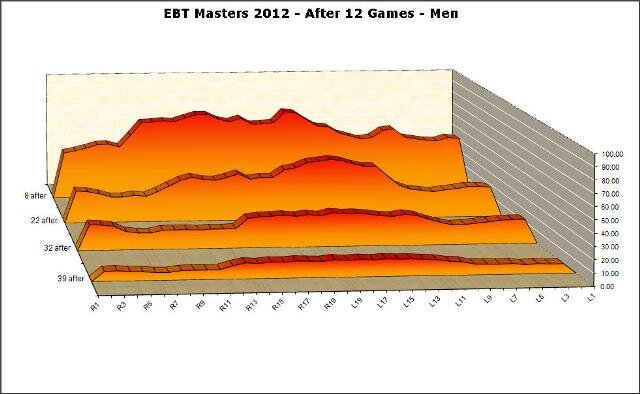

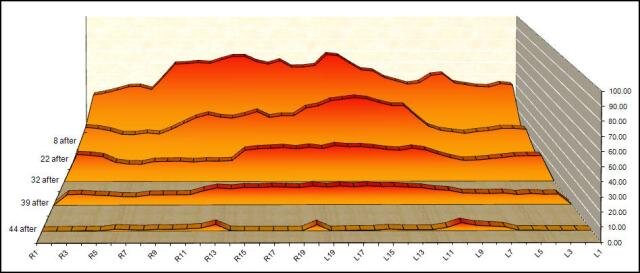

Here is the graphic of the EBT Masters pattern after one block of play by the women:

Here is the same graphic of the men’s pattern breakdown after one block of play:

You can plainly see (I hope!) that the pattern breaks down significantly different when styles/rev rates are more similar versus when styles/rev rates are more diverse.

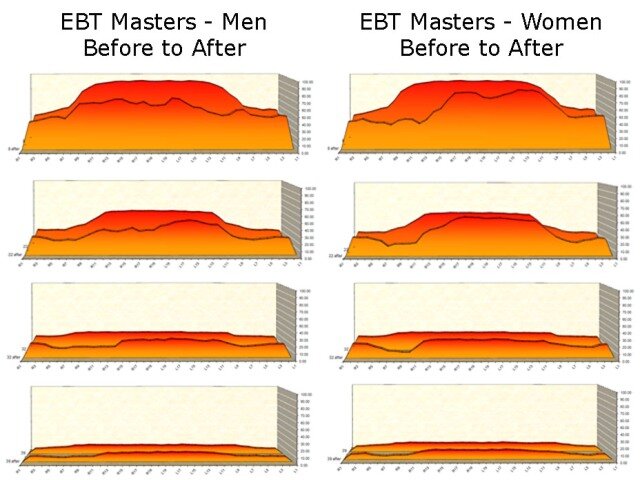

Here is a graphic of the before to after bowling between the men players and the women players at each tape distance, 8’, 22’, 32’ and 39’ (fresh oil is behind the after bowling tape):

This graphic clearly shows how the lower rev rate women players “cliff” the oil pattern much more than the men players simply because the women play in a more similar area.

But now comes the interesting part of this breakdown pictorial and data article – the numbers.

What we often track is the oil depletion in percentages from that of the fresh oil pattern. As you will see, the percentages match up to the above graphics. What might surprise you is how much each group depleted. Common thought is high rev players deplete much more conditioner than lower rev players, but is it really so?

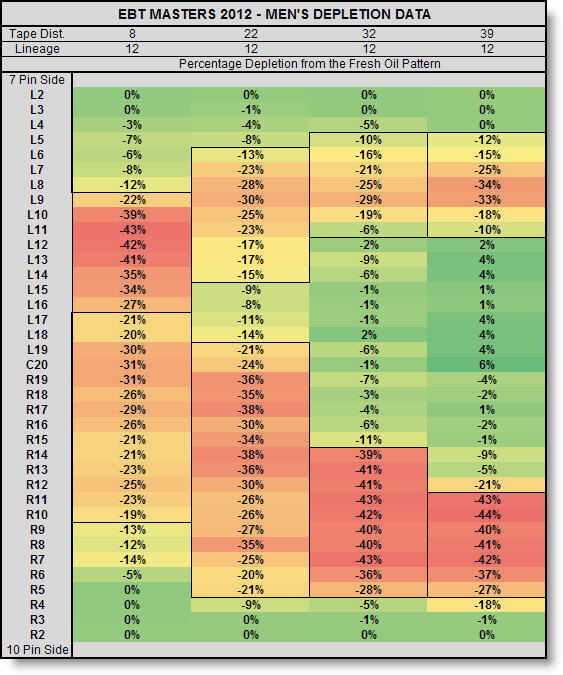

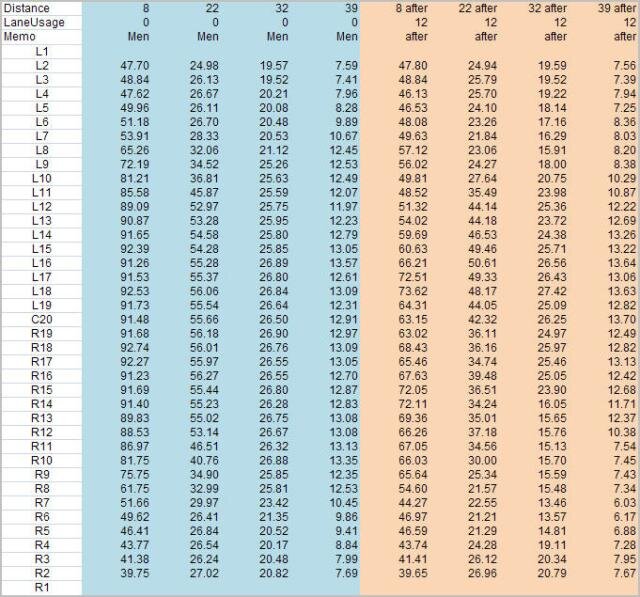

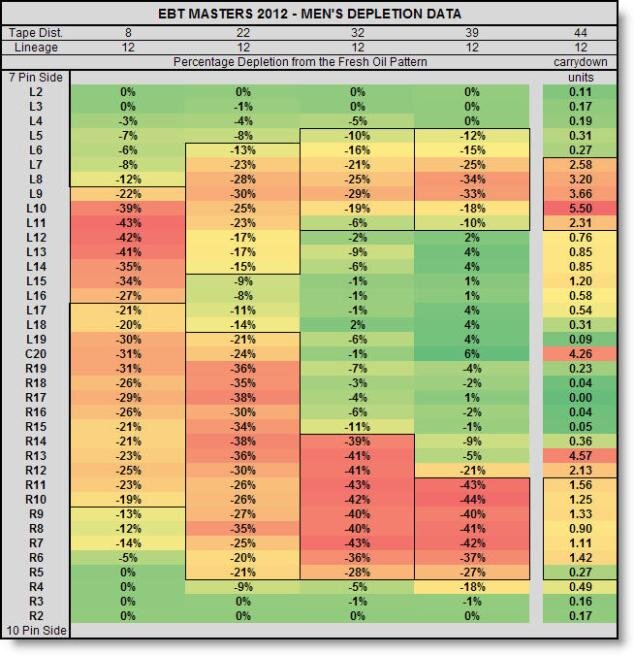

Here is the depletion by percentage on the men’s side of the event, with the square boxed area being a guide to show where the greatest depletion took place:

As you can see, the men took off about 40 plus percent at each distance throughout the oil pattern. After about 4 games of play, the right-handed players and the left-handed players came together in the fronts (8 feet) from boards L10 to L15, causing the greater depletion numbers in that area.

Before that move left, the right-handed men players continually moved towards the inside portion of the lane in their lay down area, yet they were still playing to near the same exit part of this 41’ oil pattern, between boards R5 and R11.

So how many units were left in the oil pattern after play? And what area of the depletion caused them to move left?

Here is a graphic of the before, on the left side of the graphic, and after tape data, on the right side of the graphic:

As you can plainly see, at the 8 foot distance of the pattern, after 12 games plus practice there was still over 60 units of oil on the lane. Only when the left-handers and right-handers lay down point became similar did we see the 50 unit barrier get broken, and that was only on a couple boards.

As we pointed out in the last feature article, the depletion towards the end of the oil pattern is what causes players to move left in today’s game, not “the fronts”.

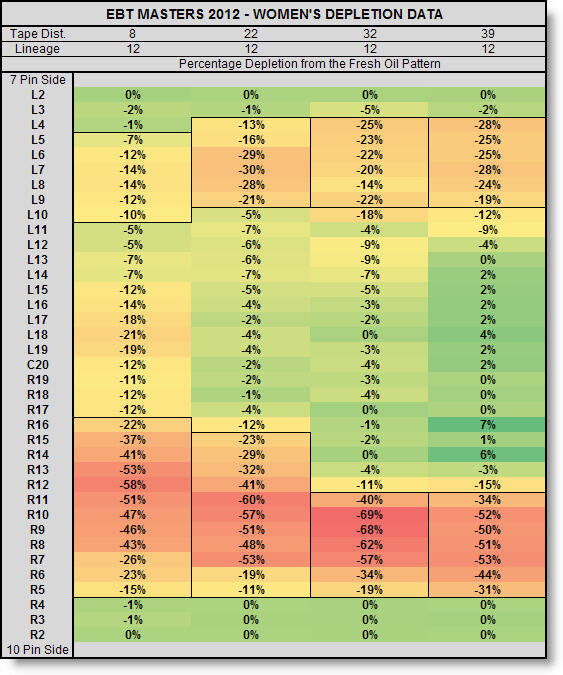

Now the depletion tape data in percentages from the women’s side of the event, and as before, the square boxed area is a guide to show where the greatest depletion took place:

As you can see, because the women’s styles are more similar, as well as their rev rates, this group tends to play in a tighter area of the lane. This causes more depletion than when everyone is spread out all over the lane.

If you notice, the greatest percentage of depletion is at the 32 foot mark. The reason is, for the women players, all shots are starting to come together at this distance and there is more oil in that area than the end of the pattern - more oil equals more change.

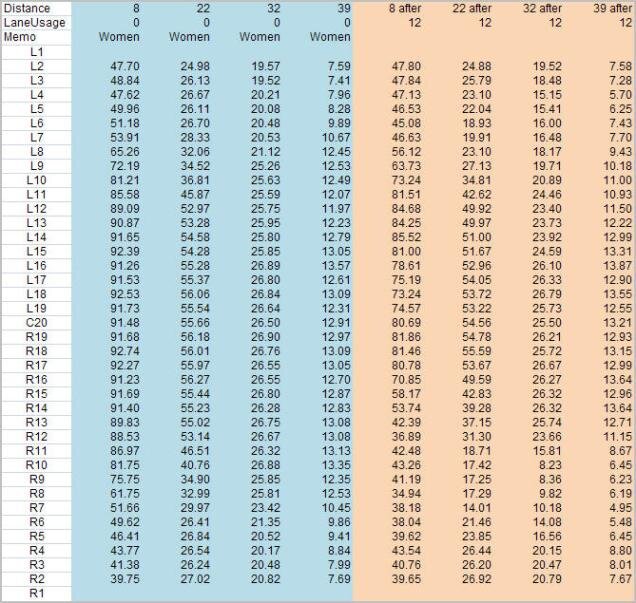

Now let’s look at the same graph of the tape data in units of a women’s block after 12 games:

As you can see by this data, the women actually erased more oil off the lane in their lay down area (8’ tape) than the men did, yet still not enough to make the ball hook early, or make them move left because “the fronts have gone away”. The end of the pattern however is once again, another story.

The women have “ganged up” on the exit point of the pattern causing the 10-12 units of fresh oil at 39 feet become 5-6 units by the end of play. At 32 feet, the fresh 25-26 units of oil became 8 units after bowling.

This back-to-front oil pattern breakdown is the cause of the players moving left, not the old school front-to-back oil pattern breakdown we used to have before bowling ball track flare became a dominant force.

Also, to give you an idea how much oil is left on the lane by each group at each tape distance after bowling, here is what the tape data showed as an average amount of units at each tape distance:

- The men players at 8’ had an average of 54.35 units left on the lane, at 22’ an average of 31.73 units, at 32’ an average of 19.93 units, and at 39’ an average of 9.84 units.

- The women players at 8’ had an average of 58.79 units left on the lane, at 22’ an average of 30.79 units, at 32’ an average of 18.60 units, and at 39’ and average of 9.40 units.

Carrydown Data

This next graph and data might surprise some people, although it will make perfect sense once explained. I have been watching this in action over the last few years and it is something as lanemen we have no control over.

During this event we took carrydown tapes of the men and we will show the same percentage graphic as before with an additional twist, the carrydown tape in units. We do this so you can plainly see the exit points within the oil pattern of both the right-handed and the left-handed players.

Here is the graphic with carrydown tape visual (left side is right side of lane, right side of graphic is left side of lane – you are still looking at these graphs from the pins perspective!):

Here is the data, depletion percentages plus carrydown in units of oil:

If we look at the blocks which show where both the left-handed and right-handed players played, you can plainly see how much carrydown is on the left side of the lane at the left-handers exit point of the pattern, yet not so much on the right-handers exit point. Why might you ask?

It is actually very simple once we think about it. We know that most spare balls in use today do not flare much, nor do they soak up oil like high flaring reactive resin strike balls that are in use today. So as right-handed players continually shoot spares on the left side of the lane, these non-flaring non-absorbent spare balls leave those long carrydown strips when they exit the oil pattern.

These ball types also do this when players are shooting spares on the right side of the lane, yet the carrydown tapes clearly do not show as much carry down at the end of the pattern.

The answer lies in the amount of high flaring balls going down the lane on the right side of the lane versus the left side of the lane.

Basically, the right-handers strike balls continually erase the carrydown left by the spare balls, but on the left side of the lane there is simply not enough high flaring absorbent balls going down the lane in that area to erase left side spare ball carrydown.

This lane condition change can be beneficial or detrimental to the left-hander. If these left side carrydown strips become dominate inside of target, like on patterns or conditions that allow the outside of the lane to play, it can give the left-hander hold area.

Yet if these spare ball carrydown strips become dominate left of target, or at their exit point, like many medium long or long patterns, it can result in a hang spot or reduced pin carry.

One more thing to be aware of with spare balls on today high volume oil patterns is how they can actually increase the amount of oil at the end of the oil pattern where high flaring balls are not traveling. We saw this happen often in the late 1980’s even where the traffic was when more aggressive coverstocks and larger core urethane balls were mostly in play. The end of the pattern after a couple blocks often had more oil on it than when fresh. It also shows up often in our after tapes in today’s game outside the track area (where most balls are being rolled), which can clearly be seen on the aforementioned data.

The reason for this today and back then is simple, by the mid to late 1980’s the amount of oil on the lane had to significantly increase in order to give the wood lane protection.

The by-product was more carrydown because more oil was being picked up by the ball in the fronts and re-deposited towards the end of the pattern and the dry back end.

This combination led to a great advantage after a few games by high rev big hook ball players as they could simply go around the carry down for return outside of target, and then the carrydown became hold area inside of target for this type player.

We see the same dominant style trend happening again today but for different reasons – this time it’s rapid depletion of the oil pattern from back to front and who can chase the oil inside of target on the lane the fastest.

Normally today, just like in the late 1980’s, it is often the high rev players who can create the largest margin of error and best angle for the best pin carry once the oil conditions are altered simply by bowling.

After reading all this you might be asking yourself what then is the best combination of ball versus lane versus oil that would minimize all this rapid lane condition change? That my friend is another article for another time…