Inside Line Tech Tips - Summer 2011

“The oil pattern didn’t play anything like it did at home!”

by John.Janawicz@kegel.net

Often times I hear this comment and there are many reasons why this can happen. Frequently, the center that you are going to bowl the tournament in (say for example the USBC Open Championships) is using a different brand of cleaner, different oil, and a different lane surface (not even taking account of one of the biggest differences….topography). Those are very obvious factors, but often people think that because they have the same lane machine as at the tournament site that it should cover all of those differences. Ultimately, even if you have the same lane surface, oil, cleaner, and lane machine, differences will still remain.

One of the differences we see often is the physical condition of the lane machine. Even though each Kegel lane machine leaves the factory meeting all of our strict adjustment and performance specifications, what happens to it from there is totally dependent on the maintenance (or lack thereof) that is given to it.

For an example, let’s compare two cars: Two 2011 Chevrolet Corvettes.

One Corvette lands in the hands of a business man who uses it strictly as a commuter car. He washes and waxes it every week, changes the oil right at 3000 miles, and always uses synthetic oil. He manages to put 25,000 miles on the car in a 12-month period.

The second Corvette ends up being a rental car. The car is in numerous drivers’ hands many of which perform routine burnouts and jackrabbit starts. This car also logs 25,000 miles in a 12-month span.

Though both of these cars started their life exactly the same, do you think both cars are going to look the same and perform the same after 12 months? Do you think the interiors are going to be the same? It wouldn’t surprise me if the rental car’s transmission doesn’t shift as crisp and probably a few of the basic items are a little more worn out (brakes, parking brake, tires, etc.) All I know is, I’ll take Corvette number 1 and you can take a chance with the rental car, haha!

Knowing this, do you think all lane machines are treated the same? We’ve seen many lane machines after one year look like they’ve never been cleaned! Oil drips out of the vacuum motor (where it never should), the transfer brush is filled with dirt and hair, the paint is peeling off due to cleaner being spilled on it numerous times, and the frame has been tweaked throwing the factory adjustments out of spec since the machine has been dropped more than a half-dozen times due to negligence.

- Do you think that this machine I described above will put out the pattern the same way the brand new machines we have at the USBC Open Championships will?

- Do you think the pattern will be the same with a machine that doesn’t clean the lane well because the squeegee blades or cushion roller have never been changed?

- Do you think the pattern will be the same even if the cleaner tank filter is clogged and the Norprene cleaner tubing hasn’t been changed in over a year which results in half the amount of cleaner coming out (resulting in poor cleaning) and now you’re oiling on top of a film?

- Do you think the pattern will be the same even if the transfer brush has so much dirt in it that it keeps the oil in the transfer brush an extra 6 feet down the lane?

Many factors will make a pattern play different from center to center but often one of the biggest is the physical condition of the machine itself. Stay up with the maintenance of the parts that commonly wear out (squeegee blades, buffer brush, cushion rollers, etc.), keep the machine clean, and your lane condition will be more consistent from week to week and month to month.

Like our VP of R&D Mark Davis once said: “Machines that look like new….tend to perform like new.”

Preparing your Lane Machine for the Fall Season

by Steve.Cross@kegel.net

As many bowling centers close during the summer months, it is especially important to properly prepare your machine to begin a new fall season. If this is not done, it can lead to restriction to flow in the system, or problems with ball reaction at an inconvenient time after the league season has begun.

In order to stay ahead of Murphy ’s Law, I urge customers to follow the Boy Scout motto and “Be Prepared.” You will thank yourself for performing this preventative maintenance on your machine.

The first thing you will need to do is get the machine out and drain the fluids. You will then want to remove both the oil and cleaner tanks individually and perform a thorough cleaning on them and the filters. Inspect the tanks to make sure there is no sediment or residue from the previous conditioner or cleaner left behind. It is important to flush and clean these tanks whether you plan to use a new batch of the same conditioner or intend to switch to a new conditioner altogether.

Once the cleaning is complete and machine is intact, you should turn the machine on and check that oil is flowing freely through the oil lines. You will be looking for a consistent PSI reading. If the pressure readings are too high or too low, this indicates that there may be a problem in the oil lines.

This is also a time of year where many centers will experiment with new oils or patterns. I always recommend that changes be tested before the season begins. This allows time for you to decide what is right for your center and make pattern changes or adjustments if necessary. If your center will be using a new oil, I suggest keeping the same pattern for testing. Changing only one of these variables will give you a better comparison of the new versus the old oil.

This should help to ensure that you maximize your machine’s performance and decrease the risk of problems sneaking up on you once your season has begun. Take care of your machine, and it will take care of you. And if it doesn’t, give one of us Techs a call US Toll Free at (800) 280 2695, or International +1 (863) 734 0200.

DC Drive Motor Maintenance

by Steve Calhoun

All Kegel lane machines are driven by DCV drive motors that are designed with two carbon style brushes, one on each side of the motor. As the brushes wear down over time, carbon dust particles build-up inside the head of the motor between the stator (field) and the rotor (armature). This build-up can cause a short inside the motor. To prevent a dangerous build-up, it is important to routinely remove the carbon brushes, and blow out the motor with air to remove any carbon build-up.

Note: If you use an air compressor, please insure that the air-lines are free of moisture before evacuating the motor.

If the brushes are several years old, they may need to be replaced. Each brush is manufactured with a tension spring that keeps the brush in constant contact with the rotor of the motor. The shorter the carbon fiber brush becomes the less tension there is on the rotor.

How to Make Your Batteries Last Longer

by John.Thrift@kegel.net

As we all know, batteries are not created equal and they do require maintenance. It is important that batteries are charged properly and to make sure the source that is using this supplied power is not abused so that they reach their maximum potential. After reading this, you should be familiar with two causes of decreased battery life and some charging standards for Odyssey batteries.

One of the biggest problems that can decrease battery life is a machine that has been abused. When a machine is not kept clean or well maintained, it can cause an overall higher amp draw and result in the battery dropping out faster.

For example, if the vacuum motor has had waste sucked into it, like the images of abused vacuum motors below, this can greatly affect the battery. Damage like this could hinder machine performance and easily cause a NEW set of batteries to do 25 lanes less than it should.

Another battery issue that is often overlooked is whether the charger is giving the batteries a proper charge. This can take into account any portion of the charging mechanism. The Odyssey batteries require different stages of charging which should be as high as 29 volts within the first 30 minutes of being on charge to as low as 27 volts after being on charge for 6-8 hours. If proper charging does not occur, this will also affect the life of your batteries.

Periodic checking of the charging system along with regular maintenance of your lane machine will greatly extend the life of your batteries.

Contact our techs at their e-mail address, or call US Toll Free at (800) 280 2695, or International +1 (863) 734 0200.

Changing Out Conditioners - Sanction Technology

KEGEL TECH TIP - The following is Kegel's recommended procedure for changing out lane conditioners in Kegel Sanction Technology lane machines.

Remove the conditioner tank from the lane machine.

Empty the conditioner tank into a container. Do not reuse the old conditioner.

Remove the internal filter from the conditioner tank.

Flush the conditioner tank out with your lane cleaner solution to get any leftover conditioner and debris out of tank. Repeat this step at least one more time.

After the lane cleaner solution rinse, rinse the conditioner tank out with water until there are no more soap bubbles to ensure all lane cleaner residue is out of the tank.

Note: Kegel recommends NOT USING isopropyl alcohol or any other solvent.Allow the conditioner tank to dry completely.

Clean or replace the internal conditioner filter.

Reinstall the internal filter using Teflon tape and a small amount of clear silicone around the threads.

Reinstall the conditioner tank.

Fill the conditioner tank with the new conditioner.

Put the return line to the conditioner tank into a separate container and run the oil pump so that the old conditioner left in the lines will go into the container. This will force the old conditioner out of the conditioner tubing and replace it with the new conditioner while also keeping the old conditioner out of conditioner tank.

Once all of the old conditioner is out of the conditioner tubing, reinstall the conditioner return line back onto the conditioner tank.

Perform an oil volume output test five times into the separate container. This allows all of the conditioner to be removed from the pencil tip and conditioner tubing leading to the pencil tip.

Before applying conditioner to the transfer system components, and depending on your machines oil application, clean the transfer brush, smoother pads or transfer rollers, and the buffer brush. No chemicals should be used to clean these items; just clean dry towels.

Allow the conditioner pump to run and inspect all connections for any leaks.

Check your conditioner volume output and conditioner pressure. Kegel suggests setting the conditioner pressure at 15 psi for machines with a CPM2A and C200 PLC’s. However, anywhere between the ranges of 10-20 psi is safe. Machines that have a CP1H PLC will run conditioner pressure NO lower than 15 psi and no higher than 45 psi. And remember, conditioner pressure and volume are independent of each other - pressure differences WILL NOT affect conditioner volume.

For questions or assistance, please contact Kegel Tech Support US Toll Free at (800) 280-2695 or e-mail at tech@kegel.net

How to Choose the Correct Lane Conditioner

If there is one thing we have learned over the years, it’s that every bowling center is uniquely different. Even two bowling centers located right down the road from each other, using the same lane machine type, with the same lane surface, and using the same chemicals, can have drastically different lane conditions.

By measuring the lanes of hundreds of bowling centers with the Kegel LaneMapper™, we have begun to further understand why bowling centers can vary so much. However, things such as the water used to dilute the lane cleaner, the temperature and humidity within the building, and the different bowler types or balls being used by those bowlers can influence what lane conditioner is best for any one bowling center.

The properties Kegel tests on lane conditioners in the lab are all physical properties. Because all physical properties are affected by the environment they are used in, it is often hard to find or suggest the “right” lane conditioner without a little trial and error. So how do you begin to select the right lane conditioner and set-up for your bowling center?

First and foremost, our recommendation is that if you are happy with the lane conditioner you are using, don’t change it. If you are not happy however, and were to contact us at Kegel, there are a number of factors we would talk you about to get you on the right path. The following will give you some insight into the process we use to make lane oil recommendations to bowling centers.

The first thing we would ask is what problems you are experiencing in your bowling center. Issues that might indicate you need to change your lane conditioner are:

Excessive ball calls

Excessive out of ranges

Pattern is not holding up long enough

Pattern adjustments seem “too touchy”

Scores are not what they used to be

Before you switch your conditioner however, consider these possibilities:

Oil pattern: Some of the problems listed above could simply be caused by the oil pattern you are using. If you notice any of these issues, it is a good idea to have an expert review a copy of your current oil pattern to determine if this could be the source of the problem. Check out our pattern library or contact our tech support

Cleaner type, mix ratio, or residue:

Sometimes oil related issues can solely be a cause of a certain cleaner or mix ratio. Make sure the cleaner you are using is designed to remove the lane conditioner you are using.

ALL cleaners leave some residue behind - even those that claim to be residue free. For example, toilet bowl cleaners that keep your toilet “cleaner for longer,” leave a small amount of residue behind to help repel the dirt. Though the toilet may be flushed frequently and appear clean, the residue remains. For an example of this residue at work, watch this “Drop Shape” video to illustrate the effect cleaner residues can have on a surface.

Lane machine: Maintenance and upkeep of the lane machine are just as important as the chemicals they apply. Machines that are kept clean and maintained will apply conditioner more accurately and leave behind smaller amounts of residue.

Lane topography: We have a new saying at Kegel after measuring 1000’s of bowling lanes; “you can’t fix a gravity problem with oil.” Checking today’s synthetic lanes at 3 predetermined distances does not give enough information to determine how your lane’s shape affects ball motion. The consistency and predominant characteristic of your bowling center’s lane topography can finally be seen with the invention of the Kegel LaneMapper which can measure 744 points on the lane.

The top factors affecting lane play are the environment and pattern choices. After that comes the conditioner choice, followed by a third and often overlooked factor, the cleaner selection. Make sure you have exhausted alternate possibilities before chasing the perfect lane conditioner.

Lane Surface type:

Synthetic brand, model and age – AMF HPL’s or SPL’s, Brunswick’s many surfaces, DBA IQ™, Murray Pathfinder™, Switch, etc.

Wood lanes with finish - 100% solids, EZ Coat, moisture cure, water-based, etc.

Type of lane machine: Do you have a fluid metering lane machine (Kegel Sanction Technology), a wick/pad lane machine, or spray type machine?

Lineage: how much of your business is league play with high flaring modern bowling balls vs. open play with low flaring house balls. If more than 50% of your lineage is from league play, you should opt for a conditioner that has high durability. If your business is predominantly open play, parties, and social bowling events, look for a lane conditioner that is geared to prevent ball calls and out of ranges such as Prodigy.

Environmental factors:

Temperature consistency

Humidity

Cleanliness

Altitude

For example, if you live in a dry desert area, there is typically high static in the air which can cause lane play issues. In this scenario, it is good to look for an oil to help prevent the snappier back ends caused by the high static environment.

Through our experience with bowling centers all over the world, we have being exposed to many different scenarios. Although we have come to find that certain generalizations can be made based on the type of situation, no two centers are EXACTLY the same.

Dennis Sheirs, Vice President of Kegel’s Chemical division often gets asked the question “What is the best lane conditioner out there?” His response is, “the best lane conditioner is whatever works best in your center.”

When choosing a conditioner for your center, it is important to get advice specific to your factors in order to determine the best lane conditioner for your center, and ultimately, for your customers. As always, if you would like to have company along that journey trying to find that perfect lane conditioner, Kegel Technicians are only a free phone call away - Kegel Tech Support (800) 280-2695.

Weather, Topography, and Ball Motion

THE INSIDE LINE: 2011/01/18

In the first issue of THE INSIDE LINE, we promised that our next article would discuss how weather affects topography and ball motion. Since lanes are made up of wood, and sub components of wood, we know temperature will affect the shape of them. However, the one part of weather that significantly affects the shape of lanes is the humidity, or lack thereof.

Because wood is porous, and high humidity means there is a lot of moisture in the air, humidity tends to make wood swell up. Low humidity, when there is very little moisture in the air, makes wood compress as the moisture is not as present in pores of the wood. For those that have seen what happens to wood approaches when a spilled drink was left there too long, you know the effects. Bowling lanes do the same thing.

Humidity and Temperature

When bowling lanes and wood based components that make up lanes are exposed to humidity and temperature changes, extra moisture in the air often "enters" the wood material at a point of least resistance. But because there are many differences in construction, and depending on the sub-foundation material and underlayment, as well as the many different wood components utilized in building a bowling lane, the only thing we can be sure of is weather definitely changes lane shape. However how it changes can vary greatly from situation-to-situation.

For instance, often the outer edges of certain materials, like wafer board Parallel Strand Lumber (PSL), are much more susceptible to moisture penetration from the sides rather than from the top. This contamination happens much faster than moisture penetration elsewhere, so in this case the swelling causes a depression.

In other instances, swelling causes the wood, or boards, to compress against each other which can cause a “push up” effect. In this case swelling can cause a crown, or less of a depression.

But how does this affect lane conditions? First, lane conditions in this case are not about the oil pattern, it’s about the condition of the lane. Time has altered the term lane conditions to mean only oil. This was not the case for the majority of time modern bowling has been in existence. So in this case, we’ll discuss lane conditions as it relates to the shape of the lane, and how those shapes affect ball motion.

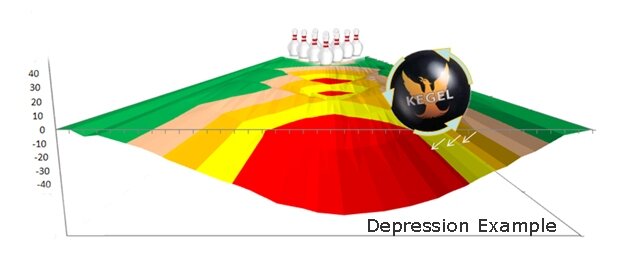

Depressions and Ball Motion

If weather change makes your lanes become depressed, this shape not only helps guide the ball towards the center of the lane, it also makes the ball lose energy faster. The reason for this increased loss of energy is the rotational effect of the bowling ball against the side hill of the depression.

Here is a graphical example:

As you can see, for a right-handed player, or left-handed back-up bowler, the rotation of the ball is counter clockwise to the slope, and therefore acts like the ball is trying to rotate uphill. This makes the ball lose energy faster versus a flat lane. When lanes are shaped in this manner, ball motion is more of an “arcing” type motion because of the early loss of energy. This loss of energy is also the root cause of why some houses are referred to as a “10-pin center”.

The majority, if not all, wood lanes are depressed, especially in the head area. The majority of synthetic lanes installed over wood lanes are depressed, especially in the front part of the lane. We have found that new synthetic lane installations are more random; some parts of the lane are depressed, some parts are crowned, some are high left, and some are high right. But they are still affected by humidity and temperature changes, which means the randomness remains, it’s just different.

We have documented examples that show certain type lane structures can depress 70/1000” when weather changes occur. To show how much this affects the bowling ball, we have taken Kegel’s adjustable lanes, shaped them, and performed many tests.

Our testing has shown that a bowling ball released at 18 mph on a lane that is depressed 40/1000” from the edge to the center, can cause the bowler to be over three boards left from that of the flat lane. Slower ball speed players and lighter balls are affected more. Faster ball speed players and heavier balls are affected less. This is in accordance with Newton’s Laws of Motion.

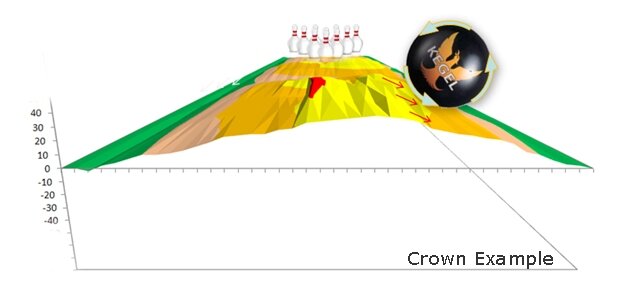

Crowns and Ball Motion

To get an idea how a crown affects the energy of the bowling ball by its rotation, here is the same type graphical example as before:

As you can see, now the bowling ball is rotating with the slope of the lane, which causes the bowling ball to lose less energy than it would if it was rotating against the slope of the lane. When a lane is crowned in this manner, high launch angles will be affected more than a bowler that plays “straighter up the boards”. When lanes are shaped in this manner, ball motion is also more “skid snappy” because the bowling ball is retaining more energy.

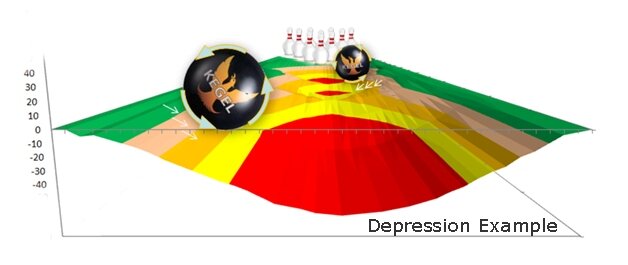

The Race Track Effect

Because of this rotational effect and gravity, lanes that are depressed in the heads act like there is very little oil in the front part of the lane. Depressed heads are no different than driving your car on a banked curve. The reason for banked curves on the road, or race track, is that they reduce the vehicle’s dependence on friction to navigate the curve.

It’s no different on a bowling lane. Depressed heads keep the ball from “squirting” away from the pocket, or in other words, help the ball make its move towards the pocket, just like a banked race track helps the car turn the corner. That is, until the bowler lays the ball down on the other side of the depression.

Did you ever wonder why players that can get far to the left make the lanes look easy? The next graphic shows why; gravity is now working to their advantage, instead of against them.

The bowling ball now has a gravity “push to the right” in the front part of the lane, and a gravity “bank shot” once down the lane. Gravity wise, the lane is helping the ball get to the right early with energy retention, and then return to the pocket in the breakpoint area. Players that don’t have the rev rate to get to the extreme left are at a tremendous disadvantage in this type of playing environment.

Notice that during this entire article, we have shown how lane shape affects the direction of the bowling ball, how lane shape affects the shape of the ball’s motion, and how lane shape affects the energy loss of the bowling ball, yet we have not mentioned lane conditioner or the oil pattern once!

The next time you start chasing down a ball motion issue at your center, or even a pin carry issue, and you have performed the Process Verification Procedure on your lane machine and oil pattern, don’t overlook the shape of your lanes. We have a relatively new saying at Kegel; “you can’t fix a gravity problem with oil.”

In conclusion, get to know your lanes; identify how they’re shaped and how weather change affects their shape. Find out why some lanes score high, and why some lanes score low. It will save you a lot of headaches, and help you provide your customers with a high-quality playing experience all year round. And like always, if you have any questions or need help, call Kegel. We are just a free phone call away.

Lane Conditions and Cold Snaps

In last month's article, we touched base on some of the effects weather can have on lane machines, lane conditioner, and ball motion. We wrote about these effects in the sense that the environment has already become more stable. But because of a few recent technical calls, we have decided to release a Special Edition of THE INSIDE LINE, and continue the discussion on how weather can affect lane conditions.

We have found that the biggest problem in a bowling center occurs when there is a drastic and quick temperature change. Kegel's lead chemist and VP of Chemical Product Development, Dennis Sheirs, found this out during the U.S. Open in 1998. For the first two days of the tournament the air conditioner wasn't working in the bowling center, and it was 80 degrees inside the center, and on the lanes.

Sometime in the middle of the afternoon on the second day of the tournament the air conditioning was fixed. Then during that evening someone cranked the air conditioning way down and by the next day both the bowling center, and the lane temperature were 60 degrees.

The bowlers started practice that morning and found the lane pattern played 10 boards tighter. Luckily, since Kegel was doing the lanes and strictly following our Process Verification Procedure, we could prove it wasn't because the laneman or lane machine did something different. But we did learn a valuable lesson; when doing lanes take control of the climate control system!

How does this affect you in daily life?

We find the same thing can happen when you typically get a cold snap up north and it's instant. Normally you will see everything get a little tighter at first. Then as everything goes through equilibrium, and bowling centers kick on the heat, all the other properties change and eventually everything will settle back in. That's when the lanes will start to hook more from the point where they got tighter at.

We said before that when the temperature of lane conditioner gets lower, the viscosity goes up, but that's only one part of the equation. The other part of the equation is the surface tension also increases, which makes the lane conditioner move more until everything settles back down. This can last over a week because during a cold snap the whole system is in flux.

What else can the weather do to my lanes?

During the summer time when the humidity is typically greater, synthetic lanes on top of wood lanes tend to be a bit more crowned towards the gutter outside of the second arrow. We know from our testing, crowned lanes tend to create "hang spots".

But in the winter time, when the heat is turned on in the bowling center or humidity decreases, the wood lane tends to depress, or the crowns decrease, and the panels follow that change in lane shape. This makes it easier for the ball move more towards the center - in other words, hook more. That change however takes a few weeks to fully occur.

If your located in an area that gradually gets colder throughout the year, you won't experience drastic changes because everything is just slowly moving there.

But from our experience, in most scenarios, those quick "cold snaps" (change from warm to cold), tend to make lanes play tighter first. Then, as the inside environment equalizes and the heater settles things down, lanes depress, and that's when we see more hook again.

So as we stated before, typically in the summertime, synthetic lanes installed over wood lanes tend to crown a little bit, and in the winter time, they tend to depress. When measuring lanes using the Kegel LaneMapper, we have documented examples of lanes changing up to .070" from summer to winter and back again - high humidity can create crowns and low humidity releases moisture causing the lane to depress.

In our research, we have found this drastic lane shape change happens only when synthetic panels are on top of existing older wood lanes. Synthetic panels on top of other substrates like MDF/HDF, or LSL do not show much change from summer to winter - only a few thousands of an inch.

Extreme lane shape change by overlays on top of wood lanes is caused by the wood lane underneath becoming "looser and looser" from years of not receiving attention as they did when resurfaced regularly. Basically, the toes screws that hold the boards together, and the screws holding the wood lane to the levelers, start backing out from the constant pounding of the bowling ball, making the wood lane act like an accordion.

Read more about Changing Lanes...

What do we suggest for quick weather changes?

Don't respond to the change too fast - give everything a chance to settle down and get back into equilibrium. Most of the time, our first response is we have to change something when somethings goes haywire - it's human nature.

You are better off to first perform your Process Verification Procedures to ensure your machine is operating correctly, your cleaner is being mixed correctly, and if so, just let everything settle down. Otherwise, you're going to be trying to change something while everything is transitioning.

A non-bowling analogy to the transition is like when you get into a pool for the first time. The water may feel cold, and that could be your first reaction, but if you stay in for a little while, you start to adjust to the temperature. Your core body temperature does not change; you just begin to acclimate to it.

After everything have settled down though, it may be entirely possible you have to adjust your oil pattern in order to keep your bowlers closer to what they are used to. For that just give us a call - the Kegel LaneMapper has provided us with insight and allows us to provide answers much quicker than in the past.

To end, and we can't stress enough, every center is unique and the solutions to any problems are just as unique. Just know that Kegel's Tech Support department is full of dedicated people trying to do the same thing you are; provide our customers with the best possible experience as we can. And don't forget, we are only a free phone call away.

Kegel Road Trip Seminar Videos

During the year 2010, Kegel, along with Storm Bowling, performed a series of seminars throughout the USA. Kegel's portion of the seminar focused on some interesting variables that make up the playing environment.

The You-Tube videos below are of Chris Chartrand presenting Kegel's portion of the seminar. After watching these videos, you will find that there are many things about bowling you probably have never thought of, or even knew about. Enjoy.

Kegel Road Trip Series - Part 1

Kegel Road Trip Series - Part 2

Kegel Road Trip Series - Part 3

Kegel Road Trip Series - Part 4

RELATED ARTICLES

Kegel's Revolutionary Slope Graphs by Ted Thompson

What a Shock - Newton Correct! by Lou Trunk

Weather, Topography, and Ball Motion by Ted Thompson

Topography: What does it all mean? by John Davis

Sir Isaac Newton Knows Bowling by Ted Thompson

The Weather’s Changing…Are Your Lane Conditions?

It’s that time of year again. Leagues began towards the end of summer, the pattern gets tweaked, and everyone starts to get back into the swing of things. Everything is going great and then boom, the weather gets colder and all of a sudden things are different. Then comes the question every manager and mechanic has heard more than they can count - "What happened?"

The products that a bowling center uses to create optimal lane conditions; like lane machines, conditioners, cleaners, and even the lanes themselves, are all physical in nature and therefore temperature dependent. So as temperature changes, the properties and performance of all those products will change as well.

So how do changes in those physical properties show up in the bowling center? They show up in lane machine performance, oil pattern differences, lane topography changes, and of course, what the bowlers feel and see in ball reaction. As the temperature of the conditioner gets colder, the viscosity, surface tension, and density all increase which not only affects ball motion, this also affects different lane machines in different ways.

For this article, we will discuss these changes and offer advice on how to minimize the effects of cold weather on lane conditions. We will focus on the products used to condition the lanes, and in the next issue, we will move on to discuss the topographical changes the lane surface goes through as the climate changes.

Lane Conditioner

In early 1997, we conducted several tests to see how much conditioners changed when the temperature was raised or lowered. What we found was eye-opening. The viscosity of some conditioners changed 2 cps (centipoises) for every 1° F of temperature change. That means if you start with a 20 cps (viscosity) conditioner and the temperature drops from 80° F to 70° F, the viscosity of that conditioner would be 40 cps.

This is not true for all lane conditioners. Some only change 1 cp for every 2° F of temperature change. That is only 25% the change as some of the others, but regardless of how much they change, it's important to know that all of them do.

To minimize this change, look for a conditioner with a higher viscosity index (VI). VI is a way of assigning a value to a conditioner’s resistance in viscosity variation as the temperature changes. The manufacturer of your conditioner should be able to give you this value and guide you accordingly.

Lane Machines

For centers using wick technology lane machines, if the conditioner or lane machine is not kept at normal room temperature, or if stored near a cold wall, the oil will “thicken” and impede the wicking action which reduces conditioner flow onto the lane. As it gets colder, the capillaries in wicks shrink, also restricting flow. Therefore the oil pattern that you started out with at the end of summer might not be the same oil pattern as the weather gets colder.

For centers using Kegel Sanction Technology™, like the IKON, FLEX, and Kustodian line of lane machines, temperature decrease will not affect the output of conditioner like it will in a wick machine. However, if the conditioner gets colder, what you may see is the pressure in your oil pump gauge increase. Fortunately, this does not change the output of conditioner; that’s the beauty of Kegel’s Sanction Technology.

For Sanction Technology lane machine owners, Kegel’s Steve Cross suggests the following when seeing slight pressure fluctuations:

- DON'T PANIC! Expect pressure fluctuations because it is normal with temperature changes.

- Do not change the tubing (pressure regulator). Many people will try to put in a shorter tube to decrease the pressure, but this is not necessary. We have designed a large margin for psi and still have the machine perform as intended. Pressure alone does not affect oil output in Sanction Technology machines.

- Do not adjust the fluid metering pump to adjust pressure. Adjusting the fluid metering pump will increase and decrease the amount of conditioner output (volume).

- Get the machine out early, turn on the oil pump motor, and let it run for about 10 minutes. You should see the psi gauge go back to normal.

Our tech support department receives many calls this time of year with temperature related concerns and we recommend the following no matter what lane machine or lane conditioner you are using:

- Keep the lane conditioner in a temperature controlled environment. The office, front desk, or wherever the temperature is most constant.

- Keep on top of your chemical orders; try to place orders a few weeks in advance to give the chemicals a chance to “acclimatize.”

- Keep the lane machine in a temperature controlled environment so the machine functions properly. If that is not possible, look for other solutions like an electric blanket, packing blanket, or a space heater to help keep the machine warm.

Ball Motion

As we stated before, when conditioner gets colder, the viscosity, surface tension, and density increase. With the increase of these physical properties, more resistance is created on the bowling ball as it rolls through the conditioner. This, in return, usually causes the bowling ball to slow down faster which means it will hook a little more.

Another byproduct of colder weather is the conditioner tends to “stay in place” more which reduces carrydown and therefore, helps the backends stay stronger longer.

Not every bowling center is affected by outside temperature changes but if yours is, our technicians have a couple tips you can employ:

- If when the weather gets colder you notice the bowling balls are hooking more, increase your oil pattern by one foot. This will help bring back the hold area you had when the season began. Once the weather warms back up, decrease the pattern length back to what it was when the season began. Note: Wood lanes with overlays can change in shape which may increase this affect; read about "Changing Lanes".

- If you find temperature changes tend to affect your lane conditions, try to use a lane conditioner that is more resistance to temperature change (higher VI index). Kegel’s Offense HV (for Sanction Technology machines only) is such a product. Offense HV was created when Kegel was entrusted with lane maintenance for the PBA Tour. It was designed to minimize the difference in ball motion from the weekly competition to the TV Show. The TV Show uses many very hot lights that are not present during the rest of the week’s competition. To this day we use Offenses HV when we perform tournaments in venues with less than ideal climate control.

Keep in mind there is no magic lane conditioner or oil pattern that is best for every lane surface or bowling center. Finding a conditioner and oil pattern that is best for your center takes some research and a lot of patience. However, as a Kegel customer you have something going for you; award winning, industry leading tech support by Kegel’s 24/7 Tech Support. Best of all, it’s only a phone call away, and it’s free!

Sir Isaac Newton Knows Bowling

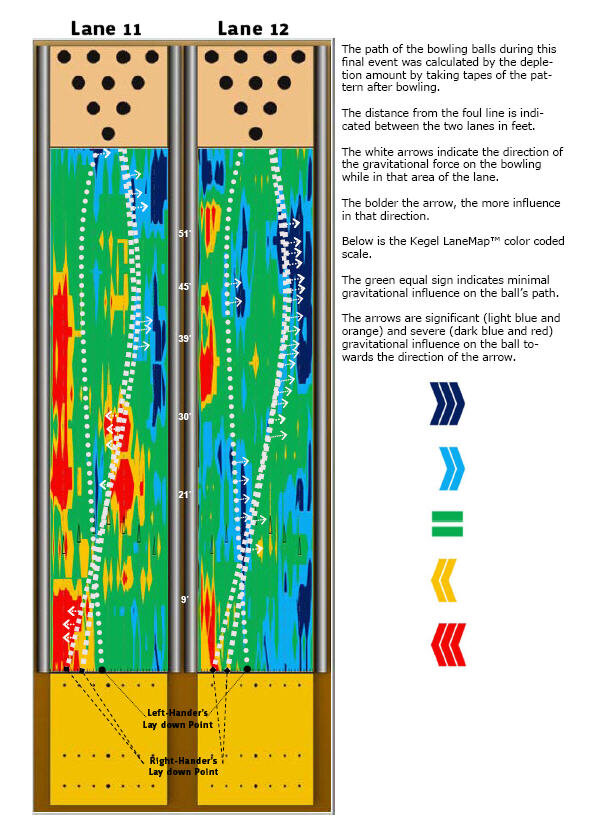

Sometimes pictures, or in this case a picture and a video, explains it best. The video below is the championship match of the Trio’s event at the recently concluded WTBA World Men’s Championship. The picture is the Kegel LaneMap™ of lanes 11-12 at Dream Bowl Palace.

The final match was played on the WTBA Mexico City oil pattern which is fairly flat and 45' in length. Our after bowling tapes showed the optimum breakpoint was around the 10-11-12 boards on that oil pattern at this championship.

The ball tracks of the left-handers and right-handers during the trios championship match are on top of the LaneMap™ Slope Graphs.

Sir Isaac Newton, the father of gravity, was not surprised with the ball motion of the players during this match - Newton has known for a long time that gravity has the same influence on the bowling ball as friction, or lack thereof.

The green areas on the LaneMap™ have very little gravitational influences on the bowling ball. The light blue and orange areas are significant gravitational influences on the bowling towards the direction of the arrows. The red and dark blue areas are severe gravitational influences on the bowling ball towards the direction of the arrows.

Now watch the video below and see if you can see and understand what Sir Isaac Newton already knew. He has been whispering in our ear for many years that it's not always oil or lack of oil (friction), as the reason the bowling ball reacts differently from one lane to the next, or even in certain areas of the same lane.

Pay attention to the right lane and how many light hits the right-handed players have. Then look at the above Slope Graphs in the break point area. Those blue areas signify a significant slope to the right - which is why the ball has a hard time moving to the left. Slopes to the right beyond the oil pattern (for a right-hander) acts like "carrydown". But it's not carrydown causing those light hits - it's gravity,