The Weather’s Changing…Are Your Lane Conditions?

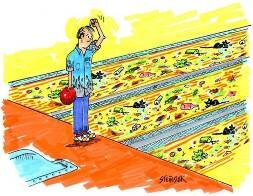

It’s that time of year again. Leagues began towards the end of summer, the pattern gets tweaked, and everyone starts to get back into the swing of things. Everything is going great and then boom, the weather gets colder and all of a sudden things are different. Then comes the question every manager and mechanic has heard more than they can count - "What happened?"

The products that a bowling center uses to create optimal lane conditions; like lane machines, conditioners, cleaners, and even the lanes themselves, are all physical in nature and therefore temperature dependent. So as temperature changes, the properties and performance of all those products will change as well.

So how do changes in those physical properties show up in the bowling center? They show up in lane machine performance, oil pattern differences, lane topography changes, and of course, what the bowlers feel and see in ball reaction. As the temperature of the conditioner gets colder, the viscosity, surface tension, and density all increase which not only affects ball motion, this also affects different lane machines in different ways.

For this article, we will discuss these changes and offer advice on how to minimize the effects of cold weather on lane conditions. We will focus on the products used to condition the lanes, and in the next issue, we will move on to discuss the topographical changes the lane surface goes through as the climate changes.

Lane Conditioner

In early 1997, we conducted several tests to see how much conditioners changed when the temperature was raised or lowered. What we found was eye-opening. The viscosity of some conditioners changed 2 cps (centipoises) for every 1° F of temperature change. That means if you start with a 20 cps (viscosity) conditioner and the temperature drops from 80° F to 70° F, the viscosity of that conditioner would be 40 cps.

This is not true for all lane conditioners. Some only change 1 cp for every 2° F of temperature change. That is only 25% the change as some of the others, but regardless of how much they change, it's important to know that all of them do.

To minimize this change, look for a conditioner with a higher viscosity index (VI). VI is a way of assigning a value to a conditioner’s resistance in viscosity variation as the temperature changes. The manufacturer of your conditioner should be able to give you this value and guide you accordingly.

Lane Machines

For centers using wick technology lane machines, if the conditioner or lane machine is not kept at normal room temperature, or if stored near a cold wall, the oil will “thicken” and impede the wicking action which reduces conditioner flow onto the lane. As it gets colder, the capillaries in wicks shrink, also restricting flow. Therefore the oil pattern that you started out with at the end of summer might not be the same oil pattern as the weather gets colder.

For centers using Kegel Sanction Technology™, like the IKON, FLEX, and Kustodian line of lane machines, temperature decrease will not affect the output of conditioner like it will in a wick machine. However, if the conditioner gets colder, what you may see is the pressure in your oil pump gauge increase. Fortunately, this does not change the output of conditioner; that’s the beauty of Kegel’s Sanction Technology.

For Sanction Technology lane machine owners, Kegel’s Steve Cross suggests the following when seeing slight pressure fluctuations:

- DON'T PANIC! Expect pressure fluctuations because it is normal with temperature changes.

- Do not change the tubing (pressure regulator). Many people will try to put in a shorter tube to decrease the pressure, but this is not necessary. We have designed a large margin for psi and still have the machine perform as intended. Pressure alone does not affect oil output in Sanction Technology machines.

- Do not adjust the fluid metering pump to adjust pressure. Adjusting the fluid metering pump will increase and decrease the amount of conditioner output (volume).

- Get the machine out early, turn on the oil pump motor, and let it run for about 10 minutes. You should see the psi gauge go back to normal.

Our tech support department receives many calls this time of year with temperature related concerns and we recommend the following no matter what lane machine or lane conditioner you are using:

- Keep the lane conditioner in a temperature controlled environment. The office, front desk, or wherever the temperature is most constant.

- Keep on top of your chemical orders; try to place orders a few weeks in advance to give the chemicals a chance to “acclimatize.”

- Keep the lane machine in a temperature controlled environment so the machine functions properly. If that is not possible, look for other solutions like an electric blanket, packing blanket, or a space heater to help keep the machine warm.

Ball Motion

As we stated before, when conditioner gets colder, the viscosity, surface tension, and density increase. With the increase of these physical properties, more resistance is created on the bowling ball as it rolls through the conditioner. This, in return, usually causes the bowling ball to slow down faster which means it will hook a little more.

Another byproduct of colder weather is the conditioner tends to “stay in place” more which reduces carrydown and therefore, helps the backends stay stronger longer.

Not every bowling center is affected by outside temperature changes but if yours is, our technicians have a couple tips you can employ:

- If when the weather gets colder you notice the bowling balls are hooking more, increase your oil pattern by one foot. This will help bring back the hold area you had when the season began. Once the weather warms back up, decrease the pattern length back to what it was when the season began. Note: Wood lanes with overlays can change in shape which may increase this affect; read about "Changing Lanes".

- If you find temperature changes tend to affect your lane conditions, try to use a lane conditioner that is more resistance to temperature change (higher VI index). Kegel’s Offense HV (for Sanction Technology machines only) is such a product. Offense HV was created when Kegel was entrusted with lane maintenance for the PBA Tour. It was designed to minimize the difference in ball motion from the weekly competition to the TV Show. The TV Show uses many very hot lights that are not present during the rest of the week’s competition. To this day we use Offenses HV when we perform tournaments in venues with less than ideal climate control.

Keep in mind there is no magic lane conditioner or oil pattern that is best for every lane surface or bowling center. Finding a conditioner and oil pattern that is best for your center takes some research and a lot of patience. However, as a Kegel customer you have something going for you; award winning, industry leading tech support by Kegel’s 24/7 Tech Support. Best of all, it’s only a phone call away, and it’s free!