Balance Approach All-In-One: What, Why, and How

Giving your bowlers consistent approach conditions from day-to-day may often seem like rocket science. There are a plethora of approach cleaners and approach conditioners on the market. And, there are an abundance of tools to help you in your quest for consistent approaches. Which ones to use; that’s the real question.

Approach cleaners help remove dirt, spills, sticky materials, and other foreign residues from the approach while approach conditioners leave an invisible film that helps reduce the coefficient of friction giving more slide-ability to the approach. These products are often great; initially. But, after a game or two, the film in the slide area gets worn and causes inconsistency between the slide-area and the corners. When this happens, the slide-area is tackier and the sides are slicker (or vice versa) leaving the bowlers with, yet again, inconsistent approach conditions.

We developed Balance with this in mind. We wanted to create a product that was simple to use and that would create a consistent slide environment for bowlers. We also wanted to create a product that would clean and condition the approach in one step.

With Balance, you no longer need a separate approach cleaner and approach conditioner; it’s an all-in-one product that can solve many of your approach problems.

Balance is gel formula that must be applied with a rotary buffer and a buffing pad. A thin bead of Balance is applied parallel to the foul line and about six or so inches in front of the foul line. Using a rotary buffer and the white or green-striped buffing pad, Balance is buffed into the approach beginning at the foul line, working backwards towards the ball return and then back to the foul line. While buffing, there is a visible film that appears. Once the film is no longer visible, the approach is complete.

The buffing pad can be used for multiple lanes. However, once the pad gets saturated, you will need to either flip the pad or use a new one. You can easily tell when the pad is saturated as it will take a long time for the film to disappear, if at all.

Balance won’t leave your approaches slick or tacky. Rather, it evens the sliding environment to make the approach consistent from gutter to gutter. It is recommended to be used weekly or as needed. Because it cleans the approaches and conditions them simultaneously, Balance eliminates the need for multiple products and saves you time by eliminating multiple steps in the approach maintenance process.

Approach maintenance no longer needs to be a difficult task that leads to consistently inconsistent approaches. With Balance, one product cleans and conditions your approaches helping you achieve even sliding approaches across your house while simplifying approach maintenance.

Synthetic Approach Maintenance

Let’s face it; approach maintenance can be a sticky, or slippery, business. There is a fine line to walk when trying to keep the approaches as consistent as possible. Some products offer too much slide causing bowlers to slip while other products can leave behind films and tacky residues that could cause bowlers to stick. Both scenarios are a recipe for disaster that could lead a bowler to an unplanned “Machuga Flop”. And while a flop can be funny, we all know it can hurt and it’s uber embarrassing. But, what is a bowling center to do? How can you maintain the delicate balance of not too slick and not too sticky? We’ve got the answers to your approach maintenance questions.

Some history

Before there were synthetic approaches, all approaches were made of wood and coated with a finish that allowed for proper slide. The only real maintenance to be done to these approaches was the occasional spot cleaning for spills and sticky marks and daily dusting. Then, once every year or so, the approach needed to be sanded and recoated to “refresh” the finish. Wooden approaches have a fairly even slide as long as the finish isn’t worn down. Once the finish started to wear, the approach could be spotty. Generally though, this was just an indication that it was time to refinish the approaches.

Synthetic approaches were introduced when synthetic lanes were introduced. Synthetic approaches were virtually maintenance-free since they eliminated the need for refinishing - or so it was thought. Synthetic approaches came with their own set of problems.

Think of synthetic approaches like your kitchen countertops; not the granite, marble, Corian, and fancy varietals, but the Formica and laminate variety. Layers of materials are pressed or bonded together and an outer layer with the approach image is pressed or bonded to the top. The top layer on which a bowler will slide is often textured and porous. This means dirt and residues can get into those tiny pores and cause build-up. It also means that repeated sliding in the middle of the approach can wear down the texture and cause inconsistencies in the slide-ability of the approach from the middle to the sides.

Because of these issues, a variety of different products and procedures have been developed to help bowling centers maintain their approaches. And what was once billed as an approach that was basically maintenance-free has now become even higher maintenance.

So what’s the right way to maintain synthetic approaches?

If I were to ask 50 different people the proper way to maintain the approach, I’d likely get many different answers. There would be variations of cleaning techniques that used various cleaners and solutions and even just hot water. There would be dust mops, wet mops, buffers, and spot cleaners. The only consistent thing would be that bowlers still complain and the approaches are inconsistent. It’s a vicious and never-ending cycle.

Synthetic approaches require temperature and humidity control. I did some digging, well, Googling, and I found that humidity over 50% can cause approaches to be tacky. We all know tacky isn’t good when trying to slide. To combat this, having some temperature control in the bowling center is absolutely necessary. Additionally, having circulation that pulls or pushes moist air away from the lanes/approaches can help keep moisture from the air from settling onto the approach. The optimal humidity is around 40%.

Dusting the approaches is a necessary task. Dust can settle on the approach and get embedded in the pores. Aside from just causing the approach to look dirty, dust can cause inconsistent slide-ability as well. Dust can cause approaches to be slick and, well, too slick is just as bad as too tacky.

Spills happen

It’s important to clean the spills and wipe away residues. Lane conditioner, soda, beer, and an infinite number of other materials can be spilled on the approaches and every one of them can cause sliding issues. When something is spilled on the approach, wipe it up as soon as possible with a clean, dry cloth. Use a weak dilution of cleaner to remove any sticky liquids. Go back over the area with another clean towel and some IPA (isopropyl alcohol). IPA is very good for removing sticky residues and leaves no residue behind of its own. It isn’t a “cleaner” but it will help remove sticky residues.

Clean those carpets and floors!

The carpets and flooring areas around the bowler’s circles must be kept clean as well. Wax from tiles and residues from carpets and carpet treatments can stick to shoes and can easily be tracked onto the approach. It’s just as important to keep the non-bowling areas clean as it is to keep the bowling areas clean. And, be careful what products you choose for cleaning. Many cleaning products leave behind residues and, as I said before, the residues can easily be tracked onto the approach.

The quest for consistency...

When all of this is done, sometimes you still need some help getting consistent slide on your approaches. There are many products on the market designed to help you with this. Unfortunately, so many of the products available have their own sets of issues. When sprayed, they can get on the lane surface and cause issues with the lane conditioner and pattern.

Dust type products can leave dust residue on the lane and the residue can settle in nearby areas. Some products have to be used very sparingly or the approach can end up being too slick. Some products work great when you first use them, but then after a couple of games, the approach is inconsistent again because the product has “worn off” in the slide area leaving the outsides slick and the slide area tacky.

All of this can be a big frustration. And, it’s one of the common complaints that we hear when dealing with approach questions. People just want a process that is simple and they just want the approaches to be consistent. In fact, I’ve heard from many bowlers that they wouldn’t mind the approaches being a little on the slick side or even a little on the tacky side as long as the approaches could be consistent from the ten pin side to the seven pin side. Bowlers can adjust for a little more slide or a little more stick. But, it’s nearly impossible to adjust when there isn’t any consistency across the approach.

To sum it up, synthetic approach maintenance can be tricky. It can be time consuming and tedious. And, with all of the approach maintenance products available, it can be downright overwhelming. But, the good news is, it doesn’t have to be. Giving your bowlers consistent approaches doesn’t have to be such a mind-boggling task. You can give your bowlers the left-to-right consistency they want on a day-to-day basis with Balance, Kegel’s new synthetic approach maintenance product. To learn more about Balance, click here.

Does lane oil evaporate and how long should the oil pattern sit?

When it comes to lane conditions, every person has their own ideas as to what they think works best. Mechanics, proprietors, and bowlers all have a difference of opinion when it comes to dressing the lanes. Ask 100 different people and you’re likely to get 100 different answers. In bowling, it’s one of those topics that just seems to create a lot of controversy and a lot of differences in opinions.

Because of all these different opinions, we get many questions regarding what the best methods are for ensuring lanes are the same from day to day. Some of these questions stem from curiosity while others, like the one I got last month, stem from bowler controversy.

I was forwarded a message that came in from our website. The proprietor was quite frustrated at his bowlers because his bowlers felt like the lanes were getting conditioned too early and the conditioner was “drying up” before they ever started bowling. The proprietor tried to show the bowlers statisitical data in their score trends that suggested otherwise. But, the bowlers just didn’t agree. So, he asked “the experts”; how long can an oil pattern sit on a lane before it starts to deteriorate?

Modern lane conditioners; every lane conditioner available in today’s market; are all mineral oil based. Kegel uses pharmaceutical grade mineral oil in our lane conditioners so it is of the highest purity available. Mineral oil itself doesn’t evaporate. You could fill a cup with mineral oil and leave it sitting and it wouldn’t evaporate. Here is a link to a safety data sheet (SDS) for white mineral oil. If you look in section 9 (page 4 of the document), it shows the evaporation rate as ‘NA’. This means there is negligible or no evaporation of the material.

There are some chemicals in lane conditioners that will evaporate but these ingredients are minor compared to the percentage of mineral oil. For example, solvents such as isopropyl alcohol (IPA) are often used as an inexpensive way to lower the surface tension. Lowering the surface tension will allow the lane conditioner to wet across the lane surface more quickly. Once the lane conditioner is applied, the IPA would evaporate over time. Since lane conditioners are applied in such a thin film with a low volume over a larger area, we would estimate this to be in the 30 minute range at most. It does not take a lot of IPA to lower the surface tension so it is used in amounts of 1% or less. This evaporation does not affect the lane play characteristics that come from the mineral oil and the other ingredients that are used to give the conditioner its characteristics.

While we’ve never tested the theory of how long a lane conditioner could sit before deterioration begins, a lane pattern could sit, well, forever without deteriorating. That is, of course, in theory since we don’t have a time machine! There are other things; environmental and atmospheric conditions; that will affect lane conditions. But, the conditioner itself could sit for days on the lane and it would still be there; it isn’t going to evaporate away.

While we haven’t tested the ‘forever’ theory, we have allowed a freshly conditioned lane to sit for 24 hours. We took tapes from the freshly applied pattern and took tapes on the same pattern 24 hours later. The results: the tapes were exactly the same for both sit times. The conditioner sitting on the lane didn’t change as a result of evaporation.

Other things can affect the conditioners performance though. Dust from the air or from AC vents can be deposited on the lane. These particles can greatly affect the playing characteristics of the pattern. This is one reason that a good cleaning routine is so important. Applying lane conditioner to a dirty lane will also affect the playing characteristics of the pattern.

Atmospheric conditions like temperature and humidity will also greatly affect lane play and these are more likely the cause of changing lane conditions. Bowling centers see this a lot as the weather changes, especially when there are sharp changes from cold to hot or hot to cold. Bowlers will complain that the lanes are tighter or drier or something else but they don’t always consider the weather changes and that can affect lane conditions significantly.

Here are two previous Inside Line articles that address changing weather and lane conditions: The Weather’s Changing… Are Your Lane Conditions? and Lane Conditions and Cold Snaps.

How long a conditioner should be allowed to sit on a lane prior to bowling is a very common question. And, it’s one that we’ve gotten many times. While consistency is key, we like to support our arguments with science. So, here’s a little science behind conditioner application.

When lane conditioner is immediately applied to a bowling lane, several things must happen before the lane conditioner stabilizes enough to provide consistent playing characteristics. One is allowing the lane conditioner to adhere to the lane surface. This takes about 15-30 minutes depending on the amount of conditioner applied, the type of conditioner, the type of cleaner being used, and the surface energy of a particular lane surface.

The surface tension of the conditioner is also important since the surface tension directly affects how the conditioner “wets” across the lane. The conditioner needs to “like” the lane in order for it to wet across. If the surface energies between the two don’t agree, the conditioner will “sit up” on the lane surface (think of this effect as little beads of water sitting on the surface of your car versus the water sheeting off the surface of the car).

Another bonding takes place within the lane conditioner molecules themselves. These bonding forces, known as van der Waals forces, are basically weak attractions between atoms, molecules, and surfaces. The time for this to take place after conditioning a bowling lane is also anywhere from 15-30 minutes. The below video shows these weak bon

With the amount of lane conditioner being used in today's lane patterns, it takes about 15-30 minutes for the lane conditioner to "settle down" and stabilize on the lane. If time is not allowed for this process to take place, things like excessive carrydown can occur. The lanes may also play "tighter" simply because the oil is sitting up on top of the lane more and there is less resistance to the bowling ball as it rolls through the oil pattern. This is one reason; during tournaments where we provide lane maintenance; we always try to get the tournament organizers to allow a minimum of 15 minutes of lane conditioner "sit time" before the first ball is thrown down the lane.

The biggest key is consistency. It’s one of the things that we preach. Create a routine and stick with that routine every day. If you do the lanes an hour before league, do them an hour before league every time and you’ll eliminate that variable (and that complaint from your bowlers).

We hope this information helps you. If you have additional questions, please feel free to contact us. We will be happy to assist in any way we can. Until next time, happy bowling!

Switching Lane Conditioners: Out with the old, in with the new!

Bowl Expo has come and gone once again. That means that summer is in full swing and league season will be upon us before you know it. As such, you may be thinking about trying a new lane conditioner, like Fire or Ice, before league season starts. These conditioners were released last year and they have been gaining attention because of their performance in tournaments and championships worldwide. Now is the perfect time to try one and get your pattern adjusted to be ready for fall.

Changing lane conditioners can be an overwhelming process. In fact, just the thought of it may send shivers down your spine. After all, if your bowlers have been happy, why change it and risk upsetting the balance? Well, technology has come a long way. We’ve worked hard developing conditioners that will help you protect your lane surface while providing a durable lane condition for your bowlers. And, we’ve improved the durability while allowing you to use less conditioner which saves you money.

Once you’ve decided to make the leap (and decided which conditioner to use – we’ll have more on that later), you’ll need to spend some time cleaning your lane machine. While it may seem easy to just empty the conditioner tank and pour in the new conditioner, you won’t be doing yourself any favors by doing this. Cross contamination from one conditioner to another in the same tank can wreak havoc on your lane pattern and make your lanes inconsistent. And that just leads to unhappy bowlers. No one wants that!

Additionally, some lane conditioners just don’t mix well with others.* This can cause things like clogged tubing, pencil tips, or even oil control valves. You can avoid a lot of headaches by taking some extra steps early on.

*The FLEX Lane Machine boasts the ability for centers to use two compatible conditioners simultaneously. Currently, Fire and Ice are the only compatible conditioners that can be used in this manner. Mixing other conditioners, such as Prodigy or Infinity, with Fire or Ice is not recommended.

Changing conditioners in the machine is a tedious process, but it is a process that is well worth it. Here is a brief overview of the process for Sanction Technology™ lane machines:

Remove the conditioner tank from the lane machine. Empty the contents of the tank into a waste container.

Use some lane cleaner to clean the conditioner tank. Add some of your lane cleaner solution directly to the tank. Swirl or shake the cleaner to get it all over the inside of the tank.

Rinse the tank with water. You’ll want to shake and swirl to be sure the tank gets completely clean. Continue rinsing until the water is clear (it will probably look milky at first) and there is no foam.

Rinse the tank with some acetone (if available) and let the tank dry. It is best to let the tank dry overnight, but give it as much time as possible. The tank needs to be completely dry before you add new conditioner.

Use this time to wipe down and perform any maintenance to the transfer system. This is also a good time to perform some cleaning and/or maintenance to the buffer brush.

Place the conditioner tank back in the machine.

Now you’re ready to fill the conditioner tank and flush the machine. We’ve detailed the entire process here: Changing Out Conditioners - Sanction Technology

So, I’m ready to fill my machine and flush the lines, but I don’t know which conditioner to use. Don’t worry; we’re here to help!

Fire and Ice have similar properties chemically but they yield different results on the lane. Both conditioners are pinsetter and house ball friendly meaning that you’ll have fewer issues in the backend. Both conditioners also have improved durability even with reduced volume.

There are a few factors that can help you decide which would be best for you. What conditioner do you use now? What is your lane surface? Do you have more open play or do you have heavy league and tournament lineage? Answering all of these will help narrow down which option will be best for your situation. Every center is unique, so as always, our Tech Support Team is available to guide you. You can also use the comparison chart below to help in your decision.

Now that you’ve got your new conditioner into your machine and ready to go, we always recommend running your normal pattern and watching ball reaction before adjusting anything. This way you’ll have an apples-to-apples comparison from conditioner to conditioner. It is highly likely, based on our experience with Fire and Ice, that pattern adjustments will be necessary.

To reap the benefits of these conditioners, your pattern should have good front to back taper. If you’re pattern doesn’t have good taper, our Tech Support Team can help you make some adjustments to maximize the performance of these conditioners. If you’re pattern does have good taper, some small adjustments may be all you need to dial in your pattern. Here are some of the common adjustments we’ve seen:

Reduced pattern volume (i.e. 50 ul to 45 ul or 40 ul)

Average pattern volume is 10-20% lower with Ice and 10-15% lower with Fire

Shortened pattern distance and/or reverse buffer drop

Reduction of applied loads

Don’t let the fear of upsetting your bowlers stop you from trying something new. You can reap the benefits of Fire and Ice with a little patience. Start now and you have the rest of the summer to fine-tune before fall leagues. You’ll enjoy the rewards of your hard work and patience when your bowlers are happy with the more durable lane conditions and you have less oil-related backend issues.

Learn more about Fire and Ice Lane Conditioners

What is "Waste" and Why You Should Care

What is “Waste?”

When most people hear the word “waste” they automatically think of chemicals or construction materials. And, they almost always think of waste as industrial and hazardous. Yet, the word waste is a very broad term that encompasses many different categories.

From your home to your bowling center, it is important to understand what waste is and how to dispose of it. With changing regulations, businesses that have been unaffected in the past, may soon learn the costs associated with improper disposal.

Residential Waste

First of all, everything that you put in your home trash can or recycle bin is considered a type of waste. Residential wastes can fall into a few different categories. Much of the waste we generate at home is recyclable. Think about the number of newspapers, magazines, cereal boxes (or other food boxes), soda cans, water bottles, and milk jugs that you use. Nearly all of those items can be recycled in some way. Recyclable wastes can be thought of as “good” waste. They cause little environmental impact and they don’t have any negative effects on humans.

But that isn’t the only kind of waste you generate in your home. Have you ever decided to paint a room? What happens to the extra paint when you’re finished with the job? You may keep it for some time but eventually it has to be discarded. Where does it go? Paints, bug sprays (pesticides), cleaning chemicals, and fertilizers are also examples of residential wastes. And, these wastes shouldn’t be thrown in your trash can. Many of these types of wastes must be disposed of more carefully as they can be hazardous to humans and the environment. In fact, many of these items are considered “household hazardous wastes”. Hazardous waste isn’t exclusive to industry; you probably have some of these types of items in your home right now.

These hazardous household wastes must be disposed of periodically and they can’t be just thrown in the trash. To assist residents in disposing of these materials, many local collection agencies arrange certain days of the week or month for residents to either put these types of items by the curb (similar to “everyday” trash) or to bring them to a designated drop off location for appropriate disposal. Items like used cooking oil and even electronics can be hazardous and should always be disposed of in a proper manner. Even light bulbs and batteries have special disposal requirements.

Commercial Waste

Businesses also generate waste. Some of the waste generated by businesses is just like the waste you generate in your home. Paper, soda cans, plastic bottles, and cardboard are all examples of wastes generated by businesses. These wastes, just like yours at home, can often be recycled and they would certainly be considered nonhazardous. But, businesses can also generate more dangerous or hazardous wastes. Hospitals and doctor’s offices have medical waste that must be disposed of properly to keep infectious diseases and germs from spreading. Industrial operations like chemical manufacturers, factories, and even construction sites all generate wastes that can be hazardous.

But, these businesses aren’t the only types that can generate such wastes. Businesses like the local bakery, the shoe store, and even the bowling center also generate waste. While these businesses may not generally create hazardous waste, they still generate waste that can’t always just go in the trash can or recycle bin.

Waste from Bowling Centers

A bowling center with a snack bar/restaurant can generate many different types of waste in each of its various operations. The snack bar/restaurant will generate food wastes, paper products and general trash, as well as wastewater from cleaning and used cooking oil from deep fryers. All of these wastes have different disposal requirements. The food waste and common trash items can generally be disposed of in a dumpster while the wastewater from cleaning; i.e. mop water, dishwashing liquids, etc.; can generally be flushed down the drain. Used cooking oil from deep fryers however, must be collected and disposed of according to specific regulations. In many cases, this material can be collected and recycled. And, in a lot of cases, the waste generator (the bowling center) may actually collect a fee from the recycler (the person who collects the waste for disposal and/or recycling). Many people would see this as a winning situation since they have to discard the cooking oil but they can make a little bit of money from the “waste” rather than having to pay someone to dispose of the oil.

The bowling center itself also has waste. Every time a lane machine moves down the lane to clean the lane and apply new lane conditioner, waste is created. The lane machine picks up a waste that is a blend of diluted lane cleaner, lane oil, and dust. Depending on the lane cleaner and lane conditioner used by the center, this waste is typically a large percentage of water. In fact, depending on the dilution ratio of the cleaner, the waste could be 90% or more water. Of the remaining percentage, a very small percentage; approximately 1%-2%; would be the lane conditioner while the rest would be lane cleaner.

The creation of this recovery tank waste is one of the most common waste questions I receive. When it comes to this waste material, everyone wants to know what to do with it and no one really wants to spend a lot of money to get rid of something that is mostly water. Unfortunately, as environmental regulations and waste disposal laws get tougher and tougher; many bowling centers are finding out the hard way that you can’t just dump this waste down the drain.

But, why can’t I just dump it down the drain? First, grease and oils are not soluble in water and tend to separate from the liquid solution. This means that when the solution travels through the pipes, the oil can settle and cause trouble; i.e. buildup which will ultimately lead to slow flow and clogging; in the piping. Secondly, oils also hamper the effective treatments that are performed at the wastewater treatment plants. In fact, it is because of this that grease traps and other type devices are required at some places.

Improper Waste Disposal

While the waste from the recovery tank of a lane machine would, in most cases, be considered nonhazardous, there are still appropriate disposal considerations that must be followed. And, to make matters even more difficult, the regulations vary by state, county, and city. Just knowing the federal regulations isn’t enough. Your state, county or city may have varying regulations so it is always important to check with the appropriate regulating authorities to determine your safest course of action. Improper waste disposal can carry hefty penalties as well as civil and criminal consequences. In fact, fines for improper disposal can be less expensive than the civil and criminal penalties imposed for the actions. And, the civil and/or criminal penalties could even include jail time!

As I mentioned previously, dumping your waste down the drain can cause problems with the sewage lines and at the wastewater treatment facility. But, it can also be traced back to the establishment as well. When sewage lines get plugged or have slow flow, maintenance workers have to clean the lines or even replace them. When this happens, the managing authorities can determine what caused the blockage. They can then pull samples from surrounding establishments to determine if the blockage was caused by one of them. By pulling samples from lines coming directly off of each of the surrounding establishments, typically, the managing authority can get at least trace amounts of the blocking materials allowing them to determine the offending establishment. They can then charge the establishment with a violation of the federal Clean Water Act. If this happens, the establishment may be required to pay for sewer line maintenance costs as well as additional water treatment costs.

Improper waste disposal can vary depending on the category of waste and the severity of the action. Improper disposal of hazardous waste would certainly be more severe and carry a harsher penalty than improper disposal of nonhazardous waste. That said imposed fines can be more than $30,000 per day! And that doesn’t even include civil or criminal penalties that could be imposed by a court. It also doesn’t include any additional treatment costs that may be imposed by the treatment facility or maintenance costs that may be required to replace or maintain sewage lines.

As I mentioned, the recovery tank waste will generally be considered nonhazardous. This is favorable as it is much less expensive to get rid of nonhazardous wastes than it is to dispose of hazardous wastes. Additionally, there are generally more options available for getting rid of nonhazardous wastes. This means you can shop around and find more cost effective alternatives which will save you some money on the bottom line. Generally speaking, depending on the number of lanes you have and the number of times you clean and condition your lanes per day, and depending on the regulations in your area, you could dispose of this waste for a few thousand dollars (or less) a year. When you start adding up the numbers for fines/penalties, it’s easy to see that the cost of appropriate disposal in one year would be far less than even one day of fines and penalties.

How to Properly Dispose of Waste

So now you’re probably wondering what you should be doing or even who to call that could help you get rid of this waste. As I mentioned before, regulations vary greatly by location so it’s extremely important that you find out what is appropriate for your area. You can always start with a call to your local waste management authority. They should be able to direct you to businesses in your area that can help you with your waste needs. You can also do an internet search for industrial waste or nonhazardous waste handlers. There are many companies around the world that can pick up and transport the waste to an appropriate facility for treatment or disposal. You can also call your local water treatment facility. They may be able to direct you to a company that can work with you. Lastly, if you use a service for a parts washer or even for oil disposal for your restaurant/snack bar, speak with your rep from those companies. They may be able to help you with this kind of waste or direct you to another company that can help you.

Waste disposal is becoming a part of operating a business and it is important, for humans and for the environment, that we dispose of all waste in the proper way. Businesses like bowling centers have generally flown under the radar. But, as regulations are becoming increasingly strict, there are increasing demands of wastewater treatment facilities, and the costs associated with treating wastewater and maintaining equipment increases, law makers and regulating authorities are taking a hard look at problems and where they are occurring. This means it is only a matter of time until your actions could come around to cost you. Taking the extra steps now to insure that you’re properly disposing of your waste may cost you a little bit of money now but it’s far less expensive than the fines and penalties you could be forced to pay, or the jail time you could serve, for improper disposal.

Oh No! My pattern is not playing the same as last year!

By Doug Dukes - Kegel Technical Sales Specialist and Kegel Pinsetter Parts

"My pattern is the same as last year but it is not playing the same" is one of the #1 lines we hear this time of year. As one of the techs at Kegel that has the privilege to not only help all of you on the phone, but to also work on lane machines in the field, let’s take a look at some overlooked parts and adjustments to your lane machine.

CLEANING - “You can’t paint the Mona Lisa on a piece of toilet paper.”

The number one overlooked problem on a lane machine is its ability to clean. Anytime a pattern adjustment is requested because they don’t play the same, our first question is “have you done a clean only”.

On Spray Jet machines, the screen check valves (153-0220) should be taken out regularly and cleaned. Lint build up on these can wreak havoc on the jet's ability to spray properly and as the check valves get weak, your spray tips can drip. If you notice that your machine is using less cleaner, it may be a good time to take these screens out and clean them. There are also two filters that cleaner passes through before it gets to the screen check valves, one in the tank (154-0212B) and one inline filter before the pump (154-8867A or 154-8887). It is always good to replace these filters every summer.

On Sprayless Cleaning Systems, you need to replace the two filters talked about above, but also your Norprene tubing in your cleaner pump (154-0861B). This style cleaner pump operates by using a set of rollers that press cleaner through this tubing every time the motor turns on. Over time, this tubing can lose its ability to allow cleaner to be pushed through it, and your volumes can be significantly reduced. Many times I have run a cleaner volume check on a lane machine and looked at the touchscreen only to realize that I was the last one to run the test during the yearly service last year!!! You guessed it……the volume was significantly lower than what it should have been.

Once you change the tubing, run a volume check and set it to your desired output and monitor this for a few weeks as the tubing breaks in. It will vary a bit during this time and a readjustment may be required, but it will settle in quickly. This should be checked on a regular basis throughout your season as well.

The cushion roller (153-8838 standard roller and 153-8839 roller with wrap), is another frequently overlooked piece to the cleaning puzzle. The size of the cushion is the key to your cleaning. If we think about how the cushion roller works, when the cloth unwinds, the cushion roller drops onto its stop bolts. When the machine is pushed onto the lane, the cushion actually lifts up off the stop bolts, and the weight of the cushion is what helps clean the lane. Simple right? If your cushion has gotten smaller over time, now it is not making full contact with the lane surface. This means it will not clean well. Mona Lisa and toilet paper soon to follow.

If you look at your cushion roller and see the “alligator skin” look, the ends are flaring out or torn and the cloth is visually pulling into the roller, or if you can wrap your hand completely around it, it is probably time to send it to greener pastures. One trick I show during service stops is releasing the tension on the cushion roller when you finish your lanes.

On machines that have the take up roll on the top, you can stand the machine in the transport position when finished and open the duster compartment. Slide the take up roll to the side and turn it 180 degrees and lock it back in place. This will relieve the pressure on the roller and when you turn the machine on to run lanes the next day, the machine will find “home” and wind the cloth back up for you. This can extend the life of your cushion and save you from headaches mid-season.

Squeegee blades (153-8204E Blue or 153-8834 Brown) normally are not overlooked, but why leave them out. Your squeegees should be flipped every six months, and changed once a year. You don’t want to leave any cleaner behind. Always check for your 1/8 to 3/16 adjustment as well, once you change or flip your blades and adjust accordingly.

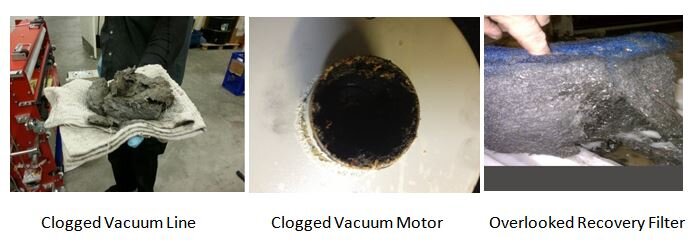

Recovery tank filters are another overlooked item in the cleaning process. Waste tank a little lighter than normal? Check your filter and change it regularly. This is the perfect time to flush out your vacuum hoses and check for small pin holes that may affect suction, along with cleaning your vacuum motor and checking the motor brushes.

Conditioning - “The best canvas deserves a worthy brush.”

A few minor adjustments in your transfer system that have been overlooked can also make you pull your hair out when you’re dialing in your pattern.

Have you checked your crush adjustments on your brush? Most people check the crush from the buffer brush to the lane and set their buffers at 1/8 to 3/16. What most people don’t check is the crush to the transfer brush or roller depending on the machine type. If it can’t pick it up off the transfer brush or roller it can’t get it to the lane!

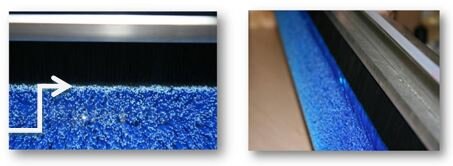

As the brush wears, it may lose some contact with the transfer brush or roller. When getting ready for the fall season with an existing brush, or when putting in a new brush, always check this adjustment. We like to see 1/8 inch of crush to the roller or transfer brush.

On a transfer brush system, if you turn the buffer on while the brush is in the down position, you should see a thin light colored line where the transfer brush and buffer brush meet. This is from the bristles on the buffer brush being pushed together as they push against the transfer brush. Adjust accordingly.

Your pressure gauge can tell you a lot about your lane machine as well. If your pressure gauge fluctuates as you are applying loads or your pressure seems much higher than normal, you may need to clean your oil control valve. Dirt can accumulate in your valve over time and cause pressure fluctuations while applying loads. If the valve is dirty, take a good look at your filter inside your oil tank as well (154-0212). Replacing it once a year will keep you in top running order.

Your lane machine is one of the most important machines in your center. My final example I tend to give to proprietors and mechanics alike goes something like this…….

If one of your pinsetters happens to go down during a league, you may upset at most the 10 people that are bowling on that pair. But you probably have the parts to be able to fix this later that evening. If your lane machine goes down, and you have a 32 lane center that is full, you’ve now made 160 people upset, and you may NOT have the parts to fix it. You next day air the parts, but your still down the next night, and 160 turns into 320. It is extremely important that you keep your machine clean, do your daily and monthly preventative maintenance, and not take your lane machine for granted. Always keep a few parts on hand. One of every relay, two of every fuse, a fuse holder, a head drive belt, check valves, etc.

This minimal list of low-cost items can be the difference between a full house of happy bowlers, or a lynch mob and a quick backdoor exit of the center. Spend ten minutes a day, 20 minutes once a week, an hour a month and a half day every six months on your machine, and you will be able to keep it clean, and inspect the machine for wear on a regular basis. Always remember we are only a phone call away 24 hours a day 7 days a week from anywhere in the world. We are ALWAYS here to help.

Good luck and good scoring on your new season.

Silicone is Not a Four Letter Word

We’ll say it right up front - silicone in lane conditioners is a good thing. That’s right, it’s a good thing. In modern chemistry there are no other additives that perform, and are as safe, as silicone.

The idea of using silicon in place of carbon did not come to be until the early 1900’s, and the first patent ever issued for a silicon containing chemical was not issued until the 1940’s. This is when the term 'silane' was developed, later to be known as silicone.

In the early years of development, silicone products were developed and used everywhere with great success. But then some problems arose with silicone, and it came from wood polishes. It was noticed that these new products repelled water, and when people started to re-coat the furniture and floors that were polished with this new stuff, they could not get the finish to wet - the finish would fish-eye everywhere. Eventually they figured out the silicone was not cleaned off the outer layer of coating and when they sanded the furniture, they literally sanded the silicone into the wood.

A similar problem occurred in the bowling industry in the late 1970’s with a lane conditioner called 42/40. That lane conditioner was silicone oil and it created a bunch of problems with re-coating a wood lane, and this is when silicone was "deemed bad" by the bowling industry.

However, it was found that you could actually re-coat wood lanes in bowling centers that used 42/40 with success and without problems, it just required more work. A fish-eye remover was required to get the finish to wet the lane surface again, and ironically, almost all fish-eye removers contain a type of silicone.

So to say something has silicone in it, and therefore it is bad, is a very generic statement. But that’s what has happened in the bowling industry.

Currently there are thousands of chemicals that contain the Si (silicon), and they can be found in everything from cleaners to adhesives. In cleaners, there are silicone based surfactants and silicon based builders, with some of these even being used in the bowling industry today.

The reason for using silicone chemistry in products is simple; performance. Most silicone additives are used in very small amounts, typically less than 0.5%. With carbon based additives on the other hand, it takes 1-3% of those less safe amounts to achieve a similar performance effect.

Kegel uses 0.1% or less of silicone chemistry in its lane conditioners to increase performance, while keeping a focus on safety. The advantage with using this technology is achieving the desired properties with maximum safety for everything the conditioner comes in contact with, and those products are tested extensively to ensure just that.

Nevertheless there are still some that like to promote their products as silicone free, as if it’s a good thing. But, the alternative chemistry available for use today is much less safe in terms of health.

Don't fall for a sales or marketing pitch on a fear of something that happened a long time ago in a much lower tech era - chemistry has come a long way over the years. If you read the material list on the back of a product in your house you will find silicone in most of them. Silicone performance and safety make it great choice for use in everyday products, and also in lane conditioner. Bottom line, silicone is a good thing.

Read more about Silicone from Dow Corning

Read more about Silicone from the American Chemistry Council

10 Things That Everyone Should Know About Lane Conditioners

There has been a lot of scuttlebutt written about the bowling ball evolution. The dramatic changes in cover-stocks, weight blocks, drilling techniques, ball reaction, you name it. What about lane conditioners? Bowlers are quick to take credit for when they bowl well and in some cases rightfully so, but we all know that when they have an off night it's seldom the bowlers fault…..it's the LANE CONDITIONS! Believe me, I'm a long-time bowler myself and I am just as guilty as the next guy. So why isn't there more information explaining the TRUTH about lane conditioners?

Today's products have numerous additives, varying viscosities, different levels of surface tension, and many other components to give oil companies reasons to proclaim that their product "Holds Up Longer", and "Doesn't Carry Down." This is all fine and dandy, but what does it all mean. The following is a list of ten very important things that everyone should know about lane conditioners. We will talk about what everything really is and why it is important when choosing or applying a particular lane conditioner. Hopefully this will help clear up some of the confusion that surrounds this mysterious invisible substance.

1. Solvent Based / 100% Solids / High Performance

Solvent Based conditioners were developed in the 40's and used primarily during the rubber and plastic bowling ball era. Some are still being manufactured and used in bowling centers today. The basic idea was that solvents would be added to the mineral oil base which would help break down dirt and aid in the cleaning process. This was very important at that time because most centers were only cleaning anywhere from once a week, once a month, or never, but who can blame them really when they were doing it by hand.

100% Solid conditioners were simply a progression to having no solvents in the formula. This was brought upon by the urethane bowling ball era and technically can be used to define most lane conditioners in production today. From the mid 80's to the mid 90's, products contained anywhere from 4-8 components with mineral oil being the main one usually accounting for about 98% of most formulas.

High Performance conditioners are becoming more popular and necessary in centers now to help combat the aggressive bowling balls. The ultimate goal of these products is to minimize change in ball reaction and maximize application consistency. The percentage of mineral oil can be as low as 75% in some formulas with the total number of components reaching the 14-16 range. These new components or additives (which we will explain later) are items such as friction modifiers and lubricity agents.

One important thing to note here is that conditioners have evolved as well. Most of our bowlers are not throwing the same bowling balls they did when older conditioners were made so it is imperative that we "Maintain Par" and move towards using products that are designed specifically for today's environment.

2. Viscosity

Definition - The measure of the internal friction of a fluid. This friction becomes apparent when a layer of a fluid is made to move in relation to another. The greater the friction, the greater amount of force required to cause this movement, which is called "shear." Highly viscous fluids therefore, require more force to move than less viscous materials. Also, the unit of measurement for viscosity is the centipoise (cps).

Importance – There are some very important things to know about viscosity. With older conditioner technology, higher viscosity generally equated to a “hookier” conditioner while lower viscosity generally equated to a “slicker” conditioner. Fancy lubricity additives and friction modifiers (which we’ll discuss later) have made this old generality untrue. Viscosity isn’t nearly as important as it once was. It still has value though; higher viscosity conditioners won’t work well; if at all; in a wick machine. And, higher viscosity conditioners may require some adjustments to pressure regulating tubing in some lane machines.

Viscosity & Lane conditioners

Second Most Important component of a lane conditioner

Lower viscosity conditioners flow better and more consistently through wicks

New additives lower the importance of viscosity

3. Surface Tension

Definition - Surface tension is a study of how well a liquid wets a solid. This is a pretty technical section so I'll do my best to keep it simple.

Most manufacturers check surface tension in relation to air. That is the number that is given on the certificate of analysis.

It can also be measured by internal liquid/solid interaction. What that means to you and me is how well a conditioner recovers, or "Self Healing", when a ball rolls through it. The goal being that the conditioner will flow back together once the ball travels through the conditioner.

Surface Tension is also directly related to surface energy. All lane surfaces have a surface energy that can be different from surface to surface and by the conditioners and cleaners applied to it. Let me give you an example:

If you apply wax to the surface of your car the water will bead up and not "wet" your hood. The energy of the hood was changed and you will protect the paint because the water will not penetrate.

Our goal with lane conditioner is the exact opposite. We don't want the conditioner to bead up, we want it to lye down and form a bond to the surface. This helps create durability and also helps enhance the self-healing characteristics.

Importance - Studies are being done now on this topic that will help us gain some valuable ground on today's bowling balls. There are also complimentary studies testing the relationship with conditioners and bowling ball cover-stocks. The perfect lane conditioner is one that likes the lane and not the ball giving us ultimate durability. I hear the Trojan horse is on its way.

4. Temperature

Effects on Lane Conditioner - I can't say enough of how important temperature is to lane conditioners. Many people have their theories about how lane conditions change when the weather changes so we decided to get some hard facts.

In early 1997, we conducted several tests to see how much conditioners changed when the temperature was raised or lowered. What we found was eye-opening. The viscosity of some conditioners changed 2 cps (centipoises) for every 1ºF of temperature change. That means if you start with a 20cps (viscosity) conditioner and the temperature drops from 80 ºF to 70ºF, the viscosity of that conditioner would be 40cps. This is not true for all lane conditioners. Some only change 1cp for every 2º F of temperature change. That is only 25% the change as some of the others, BUT regardless of how much they change it's important to know that all of them do.

Temperature affects the molecules of lane conditioners by causing them to slow down when cold or speed up when hot. Think of water turning to ice and water boiling.

Temperature will affect the viscosity, which in turn also changes the flow rate through wicks.

When the viscosity of the conditioner is changed the ball reaction will also be different as a result.

The capillaries in most wicks will shrink up when it gets colder restricting flow.

Tips:

Keep the lane conditioner in a temperature controlled environment. (Office, Front Desk, or wherever the temperature is constant)

Keep the lane machine in a temperature controlled environment so the machine functions properly as well. We understand that this may not be possible in all situations so you can look for other solutions like an electric blanket or a space heater to keep the machine warm.

5. Order of Addition

Definition - The order of which ingredients are combined in a formula to create a desired result.

This is just a little inside information to share about the sensitivity of lane conditioners. If I was given the ingredients to one of today's conditioners, not only what was in the formula, but also how much of each, I still would have no shot at making the product.

The order and timing in which the components are added together is equally as important as the components themselves. When mixing a cocktail the order is always: ice, liquor, and then mixer. If we poured the liquor in a drink last what would happen? The liquor would float on the mixer. This is simply because the density of the mixer is usually greater than the liquor.

The main thing to understand is that there is more actual "chemistry", not just "mixing" taking place with today's products.

Tip: Leave the mixing to the chemists. Some centers are mixing different conditioners with some success, BUT we do not advise doing so based on the technical make-up of conditioners today.

6. Additives

Definition - The components added to a lane conditioner formula to enhance performance and to create desirable changes to the physical properties.

There are many things that we expect from our chosen lane conditioner. We expect it to be slick, but not too slick because of ball calls. We expect durability, but some breakdown for the lanes to open up. We also expect the infamous, "NO CARRY DOWN." Trust me, if you see a company's ad saying their oil does not carry down, don't believe it. If it's liquid, it moves. ALL OILS CARRY DOWN.

However, different additives are used to minimize the carry down and create an illusion so the ball doesn't see what the eyes do. That means some conditioners use a tacky mineral oil so ball reaction doesn't change when oil is carried down.

Some of the additives used are:

Friction Modifiers - Designed to reduce friction

Viscosity Modifiers - Designed to change the viscosity

Flow Agents - Used to enhance the flow properties of a conditioner through wicks.

Lubricity Agents - A spin-off of the friction modifier to enhance the lubricity of a conditioner

Surfactants - Short for "Surface Active Agents." These additives change how a conditioner "wets" or spreads out on the lane. They also control how well a lane conditioner flows back together when a ball rolls through.

7. Quality Assurance

Definition - Quality procedures that aim to PREVENT non-conformities.

I think every mechanic will raise their hand when asked the question, "Have you ever had a bad jug of Oil?" Unfortunately, this job continues to get more difficult by the day.

All lane conditioners are made with raw materials and various additives. Mineral Oil is a true Raw Material whereas most additives are made by chemical manufacturers by other raw materials.

Here's the process when lane conditioner is different:

The bowler complains to the mechanic or manager.

The mechanic or manager complains to the distributor.

The distributor complains to the manufacturer.

The manufacturer complains to the raw material manufacturer.

The raw material manufacturer complains to the ground.

Who's to Blame? Manufacturers today are forced to test all raw materials before they are used in production. Adjustments are commonly made to the overall formula to compensate for any changes in the materials.

Think about manufacturing lane conditioner like making your favorite recipe. Let's say that favorite dish is Lasagna. One of the main ingredients in lasagna is meat. If the meat you purchased last time had more salt in it than the meat you purchased for this batch of Lasagna you would be forced to add more salt so the dish tastes the same.

I know this example may seem like a stretch, and making lane conditioner is much harder than making lasagna, but in many ways they are the same. Chemists and Cooks are constantly trying different ingredients in search for the magic recipe. In relation to Quality Assurance, they both have to test and make sure that all the ingredients are the same before using and make adjustments to compensate for inconsistencies.

8. Quality Control

Definition - Quality procedures that aim to "DETECT" non-conformities.

Quality Control is an equally important procedure as Quality Assurance. Its role is to detect any non-conformities or changes in the product after it has been manufactured. These include a series of tests to check the viscosity, weight, surface tension, UV additive, and flow rate.

Some manufactures also use a variety of on-lane tests that ensure ball reaction and breakdown is the same as well. This is basically a big giant "DOUBLE CHECKING" of the finished product before it is shipped.

Continuing on the food theme this can be viewed as the taste test before a meal is served. Together QA and QC perform a specific and very important role. They guarantee that a finished product is exactly what it's supposed to be.

Tip: Find out what procedures your manufacturer uses for QA and QC. Make sure that you feel confident that your chosen brand is doing everything it takes to ensure product consistency.

9. Shelf Life

Definition - The amount of time determined by a manufacturer that their product must be used by in order to guarantee satisfaction and consistency.

We've already explained that mineral oil is the main component in lane conditioners. Mineral oil alone has a very long shelf life. Because the newer conditioners use less mineral oil to make room for other components the shelf life is not as long, ranging from 12 to 18 months.

Think about the shelf life of common food items such as milk and bread. When the ingredients are exposed to air they will deteriorate and lose their originality at a faster rate.

When raw materials are used for lane conditioners, they too are taken out of their natural state and exposed to air. This simple fact has forced the manufactures to advertise a shelf life in order to guarantee product consistency.

Tip: Find out what the published shelf life is on whatever conditioner you are using and follow that recommendation. Usually you can find the manufactured date somewhere on the container or packaging. If you're unable to locate it, or can't understand the numbers contact the manufacturer for assistance.

10. Environment

Definition - The set of circumstances that exist in your bowling center(s).

Finally we get to the big question; how do you know what conditioner is right for you or how do you properly apply the one you are currently using? The answer is…..Understand the circumstances that make up the ENVIRONMENT in your center. Here is a checklist of the items that determine conditioner selection and application:

Lane Machine Type

Lane Conditioner Type (Existing)

Lane Cleaner Type (Existing)

Dilution Ratio

Pattern and Cleaner Settings

Type of Surface

Condition of Surface (Be Honest!)

Topography (If Known)

What type of bowlers do you have in your center?

Where are your bowlers used to playing?

What are you looking to achieve by changing conditioner or your pattern?

These criteria will help guide you towards the solution. I wish I could tell you that there is a magic lane conditioner, but there isn't. I wish I could tell you that there is a magic lane pattern, but there isn't.

The best advice I can give would be to call the experts for help. Most manufacturers have one or more trained technicians on staff to help with this problem. For years, bowling centers have struggled with lane conditions independently trying to figure out this complicated problem with limited information.

Now there are places that are collecting data about many different situations to help bowling centers not make the same mistakes that another center has already made.

In conclusion, I don't think that the natural tendency of bowlers to look elsewhere for poor performance will ever change. But by gaining more knowledge on your part you can feel more comfortable when you say;

"I DID EM' THE SAME!"